المدونة

توفر شركة ديلكو للصمامات حلولاً متنوعة ومثالية للصمامات الصناعية، خاصة لصمامات التحكم.

- الصفحة الرئيسية

- "

- المدونة

- "

- مقدمة عن صمام الفراشة الكهربائي المقاوم للانفجار

العلامات

اتصل بنا

مقدمة عن صمام الفراشة الكهربائي المقاوم للانفجار

- صمام ديلكو

Today, let’s dive into the world of electric explosion-proof butterfly valves. These nifty devices are all about safety and efficiency rolled into one. Imagine a valve that’s not only easy to use but also tough enough to handle the pressure. Curious to learn more? Let’s get started!

What is a electric explosion-proof butterfly valve

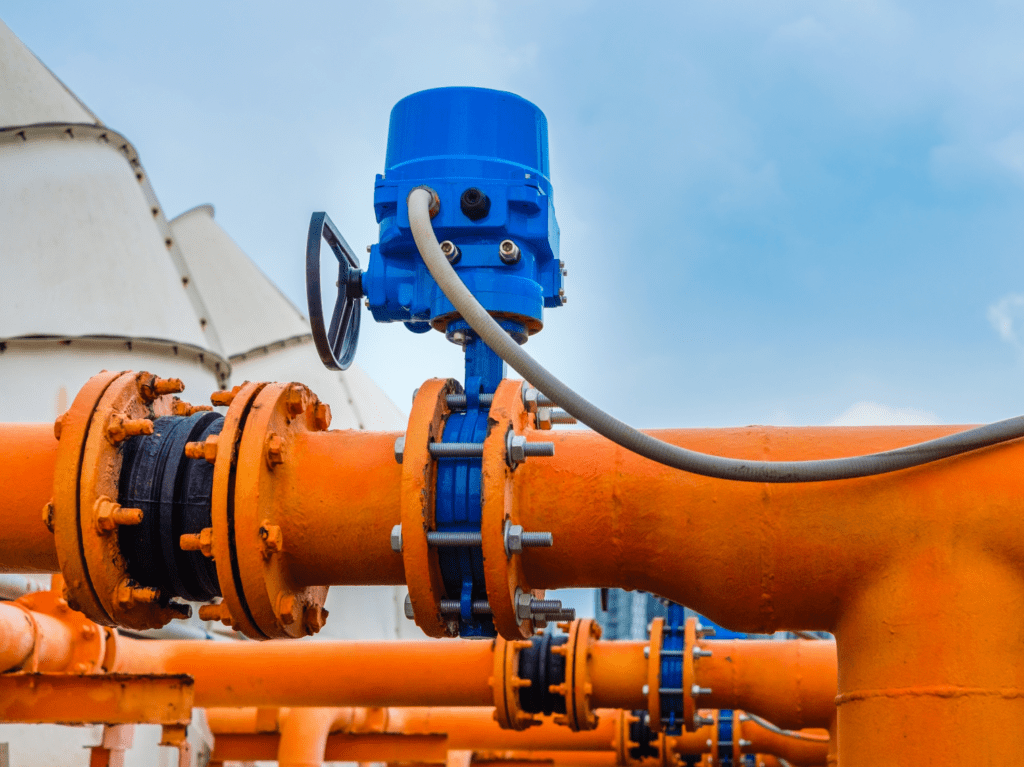

Electric explosion-proof butterfly valve is a kind of butterfly valve equipped with explosion-proof electric actuator, the valve stem is through-stem structure, after tempering treatment, it has good comprehensive mechanical properties and corrosion resistance, anti-scratch. Electric explosion-proof butterfly valve opening and closing the valve stem only for rotary movement without lifting operation, the packing of the valve stem is not easy to destroy, reliable sealing.

Principle of electric explosion-proof butterfly valve

The design principle of the electric explosion-proof butterfly valve is to enclose the parts that may cause an explosion in a shell that can withstand pressure, ensuring that the shell will not be damaged when an explosion occurs inside. The structure of the shell can isolate the internal and external environment of the equipment, and when an explosion occurs, the shell can withstand the pressure and prevent the flame from spreading, ensuring that the external environment will not be affected. This design is intended to prevent the spread of explosion and safeguard the surrounding environment.

Features of electric explosion-proof butterfly valve

- Simple structure: electric explosion-proof butterfly valve has simple structure, small volume, light weight and small installation size.

- Efficient control: it can be quickly switched on and off, 90°reciprocating rotary, small driving torque, and is suitable for cutting off, connecting and regulating pipeline medium.

- Excellent sealing performance: it has good fluid control characteristics and closing sealing performance, and can realize good sealing under low pressure.

- Energy-saving design: butterfly plate streamline design, reduce fluid resistance, energy saving and high efficiency.

- Corrosion resistance: the valve stem is tempered and has good comprehensive mechanical properties and corrosion resistance.

- A variety of connection methods: flange connection, butt-clamp connection, butt-welding connection and other methods can be used, and the drive form is rich, which can be controlled from a distance and automated operation.

Precautions for the use of explosion-proof electric butterfly valve

- Do not use too much force during operation, so as not to cause damage to the equipment, should keep the force uniform, do not use additional lengthening lever.

- Regularly check whether the nut is loose and tighten it in time to ensure the stability and safety of the equipment.

- Regularly check the packing and sealing gasket, and replace them in time to prevent leakage if any problem is found.

- The torque limit of the actuator needs to be readjusted after maintenance to ensure the normal operation of the equipment.

- Long-term storage of butterfly valves should be regularly inspected and cleaned, anti-rust treatment, keep dry and ventilated.

- Pay attention to the observation of the operation, if found abnormalities should stop running, notify the professionals to check.

- After the repair is completed, carry out the sealing performance test, compare the standard values, and exclude potential hidden dangers.

الخاتمة

ديلكو‘s electric explosion-proof butterfly valves are known for their safe and reliable design and excellent features. These valves have a variety of features. DELCO’s electric explosion-proof butterfly valves not only reflect high quality and reliability, but also focus on user experience and environmental protection, providing users with safer and more efficient fluid control solutions.

إذا كانت لديك أسئلة حول الصمامات أو كنت ترغب في الحصول على عرض أسعار، فلا تتردد في الاتصال بنا، وسوف نقوم بالرد خلال 6 ساعات. هاتف +86 159 8960 2972، واتساب +86 159 8960 2972 أو البريد الإلكتروني التسويقي [email protected].