BLOG

DELCO Valve poskytuje různá optimální řešení pro průmyslové ventily, zejména pro regulační ventily.

TAGY

Kontaktujte nás

Co je ruční tenký kulový ventil?

- Dobré ráno, Jiang

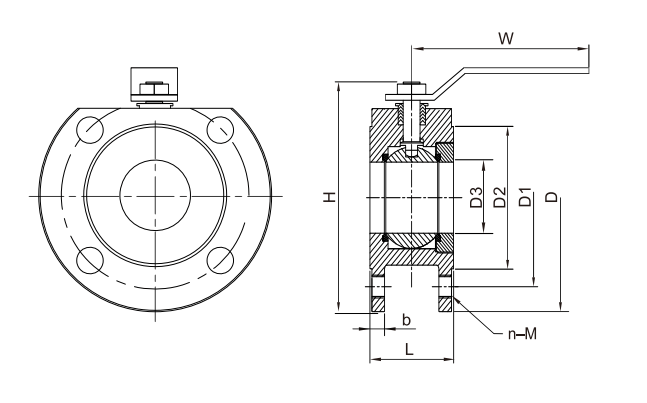

Ruční tenký kulový ventil is a new generation of ultra-short flange distance ball valve which is designed by introducing Italian technology and localization. It is widely used in petroleum, chemical, metallurgy, electric power, light industry and other fields, used to regulate or cut off the flow of oil, water, gas and pulp or fibrous fluid, the following is a detailed introduction of manual thin type butt-clamping ball valve.

1. Structural features

Thin design: compared with traditional kulové kohouty, the valve adopts a compact and lightweight design, ideal for applications where space is limited and weight needs to be considered.

Clamped flange connection: Designed to be clamped between two flanges in the pipeline, the clamped connection simplifies the installation and disassembly process, without the need to make major changes to the pipeline. Reduces installation costs.

Manual operation: Fitted with a handle or handwheel, the valve is operated by manual rotation, making operation simple and intuitive.

Italian Craftsmanship: Known for its precision engineering and quality materials to ensure reliable performance and long service life, which features a stylish design and meticulous attention to detail, reflecting the high standards of Italian craftsmanship.

2. Working principle

The manual thin-clamp ball valve controls the flow of fluid by rotating the spool (a ball with a through-hole). When the through-hole of the sphere is in the same direction as the pipeline, the fluid can pass freely; when the sphere is rotated 90 degrees and the through-hole is perpendicular to the pipeline direction, the fluid is blocked.

3. Material and structure

Main material: usually made of high-grade stainless steel, carbon steel or alloy steel, depending on the working medium and working conditions.

Sealing material: The sealing ring usually adopts PTFE (polytetrafluoroethylene), rubber and other materials to ensure that the valve has good sealing performance in high temperature, high pressure or corrosive media.

4. Advantages of manual thin wafer type ball valve

Compact, lightweight and beautiful: Thin and stylish design, suitable for installation in places with limited space and weight, reflecting the quality and craftsmanship of Made in Italy.

High quality construction: Italian engineering ensures durability, reliability and long service life.

Ease of Operation: Manual controls are simple and straightforward, eliminating the need for complex control systems and utilizing high quality components for smooth operation.

Outstanding sealing performance: Advanced sealing materials and design ensure a tight seal, preventing leakage and ensuring efficient flow control.

Easy Maintenance: The clamped connection makes the valve very easy to install and remove, easy to maintain and replace.

5.Manual thin wafer type ball valves are used in the following many industries because of their sturdy structure and reliable performance:

Water treatment system: used to regulate the flow of water in the water supply and drainage system.

Oil and gas industry: used to switch and control the flow of oil and gas in the pipeline.

Chemical Processing: For handling corrosive chemicals and maintaining precise control during chemical processes.

Food and Pharmaceutical Industry: Stainless steel products that meet strict hygiene standards are used in the food and pharmaceutical industries.

6. Manual thin wafer type ball valve maintenance and repair

Regular Inspection: Check regularly for wear, leakage or other problems.

Cleaning: Keep the valve clean to prevent impurities from entering the valve body to affect the performance of the valve.

Lubrication: Regularly lubricate the rotating parts of the handle or handwheel to ensure smooth and convenient operation.

7. Závěr

In summary, manual thin Italian wafer ball valves are highly regarded for their superior quality, precision engineering and reliable performance. They provide effective solutions for fluid control in a variety of industrial applications and are widely applicable in industrial applications.