BLOG

DELCO Valve leverer forskellige optimale løsninger til industrielle ventiler, især til reguleringsventiler.

TAGS

Kontakt os

Pneumatisk kugleventil med gevind i to dele af rustfrit stål

- Morgen Jiang

In the dynamic world of fluid control systems, the pneumatic stainless steel two-piece threaded ball valve stands out as a versatile and reliable component. Suitable for transporting water, steam, oil, acetic acid, nitric acid and many other media The perfect combination of durability, efficiency and precision. In this article, we will explore the features, benefits and application aspects of pneumatic valves, explaining why they are favoured by many professionals.

Pneumatic Valves Features from the Name Breakdown

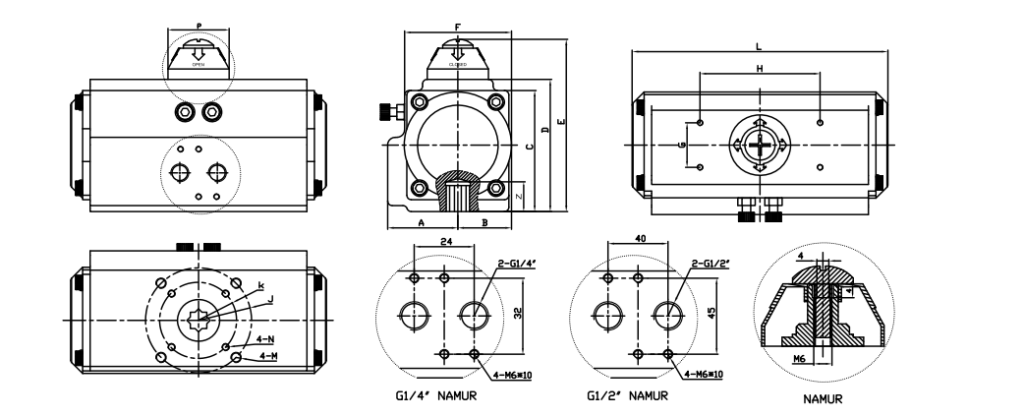

1.Pneumatic Actuation.

Pneumatic actuation provides automatic and remote control capabilities. The actuator uses compressed air to operate the valve for fast and efficient opening and closing. This automation improves operational efficiency and reduces the need for manual intervention.

2. Rugged Stainless Steel: The pneumatic stainless steel two-piece threaded

The body of the pneumatic stainless steel two-piece threaded ball valve is made of stainless steel (304 or 316). This material ensures superior corrosion resistance, making the valve suitable for use in harsh environments and a variety of media, including chemicals, water and gases.

3. Two-piece design.

The two-piece design makes these valves easy to maintain and repair. The valve body can be disassembled into two parts, allowing easy access to the internal components without removing the entire valve. This feature significantly reduces downtime and maintenance costs.

4. Ball Valve Construction Threaded End.

Ball valves are simple to construct and easy to service. Equipped with NPT (National Pipe Thread) or BSP (British Standard Pipe Thread) threaded ends, these valves provide simple and reliable piping connections. The threaded design ensures a tight seal, minimising the risk of leakage and improving system integrity.

5. Full bore design.

The full bore (or full size) design ensures that the valve’s internal diameter matches the pipe, minimising pressure drop and ensuring smooth flow. When fully open or fully closed, media passes through without causing erosion of the valve sealing surfaces;

1. Durability and longevity.

Stainless steel construction provides superior durability and extends the life of the valve even under harsh conditions, and its corrosion resistance makes it ideal for industries such as chemical processing, food and beverage, and pharmaceuticals.

2. Versatility.

Due to their robust design and compatibility with a wide range of media, these valves are suitable for a wide range of applications. Sizes can range from a few millimetres to several metres, and they operate reliably whether they are handling corrosive chemicals, steam, high pressure, high vacuum or potable water.

3. Ease of installation and maintenance.

Threaded ends simplify installation, while the two-piece design allows for easy removal and maintenance. This ease of use translates into cost savings in installation and long-term maintenance.

4. Increased Safety: Pneumatic actuation provides increased safety through remote operation.

Pneumatic actuation provides increased safety through remote operation, reducing the need for operators to be in close proximity to potentially hazardous media. In addition, the precise control provided by pneumatic actuators ensures reliable and consistent operation.

Common Applications

1. Chemical Processing.

In chemical plants, where corrosive and hazardous substances are handled, pneumatic valves provide the necessary durability and resistance to ensure safe and efficient operation.

2. Food and Beverage: Stainless steel construction and sanitary design allow these valves to be used in a variety of applications.

Stainless steel construction and hygienic design make these valves suitable for use in the food and beverage industry, where cleanliness and resistance to contamination are critical.

3. Pharmaceutical.

In pharmaceutical manufacturing, maintaining aseptic conditions and precise control of fluid flow is critical. These valves fulfil the stringent requirements of this industry.

4. Water Treatment.

For water treatment facilities, these valves provide reliable control over the flow of water and chemicals used in the treatment process, ensuring optimum system performance.

5. oil and gas.

In the oil and gas industry, where equipment is exposed to extreme conditions, the durability and reliability of pneumatic stainless steel two-piece threaded ball valves make them ideal for controlling the flow of oil, gas and other hydrocarbons.

Konklusion

Pneumatic stainless steel two-piece threaded ball valves are the embodiment of engineering excellence, combining rugged construction, versatile design and reliable performance. Its wide range of applications and many advantages make it a resident guest in any fluid control system. Whether you are looking to improve operational efficiency, ensure safety or reduce maintenance costs, pneumatically actuated stainless steel two-piece threaded ball valves are a reliable and efficient solution.