BLOG

DELCO Valve leverer forskellige optimale løsninger til industrielle ventiler, især til reguleringsventiler.

TAGS

Kontakt os

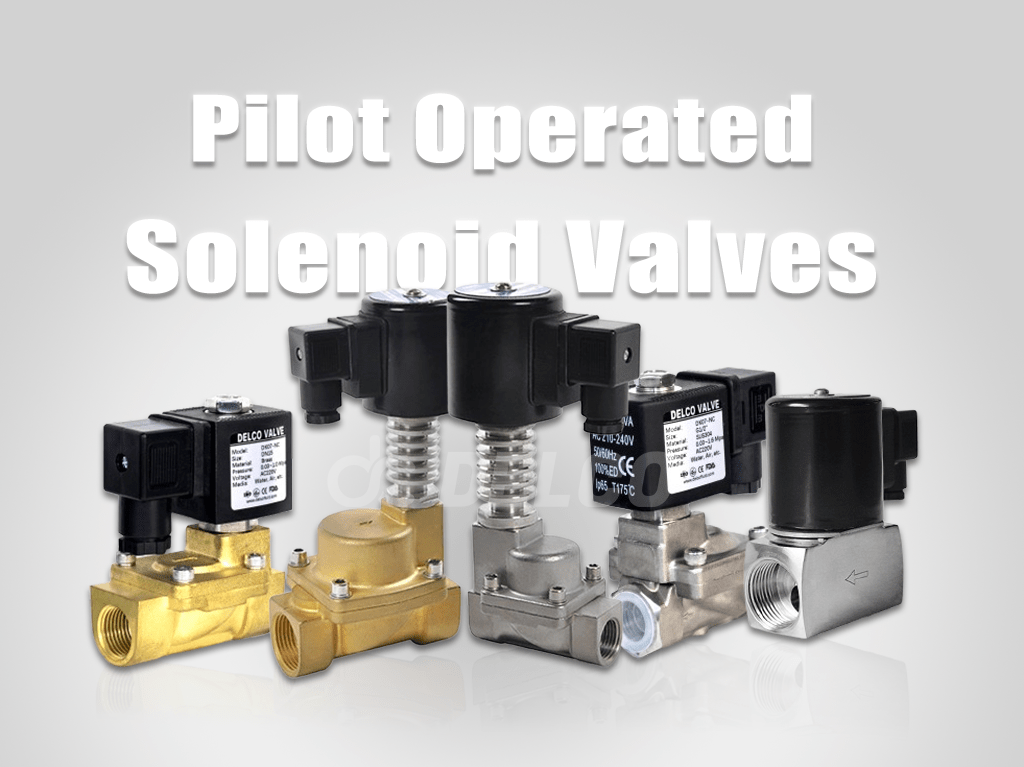

Introduktion til pilotbetjente magnetventiler

- DELCO-ventil

Pilot operated solenoid valves play a vital role in automated control systems as an advanced control element. Compared with direct-acting solenoid valves, it not only has higher flow regulation accuracy and wider pressure control range, but also can be applied to more flexible scenarios. This article will introduce the working principle of pilot operated solenoid valves and discuss their wide range of applications in various industries.

Pilot operated solenoid valve composition

- Main valve body: including valve seat, spool, spring and other components, the main spool under normal conditions by the spring force to remain in a certain position, control the media flow path open or closed.

- Pilot valve: built-in solenoid coil, when energized to produce magnetic force suction core (or diaphragm), thus changing the pressure distribution in the pilot flow path, which in turn affects the action of the main valve.

- Connection piping: transmits the pressure change generated by the pilot valve to the main valve, enabling it to switch according to the state of the pilot valve.

Working principle of pilot operated solenoid valve

When a pilot operated solenoid valve is energized, the solenoid coil will attract the moving iron core, causing it to rise rapidly and open the pilot orifice. This causes the pressure in the upper chamber of the piston to be released through the pilot hole, leaving the piston in a low-pressure state. At the same time, the lower chamber of the piston is pushed by the pressure of the medium, causing the piston to rise, thus opening the solenoid valve and allowing the medium to flow.

When the pilot solenoid valve disconnect the power supply, the magnetic force of the solenoid coil disappears, and the moving iron core will quickly close the pilot hole under the action of the spring. This causes the pressure in the upper chamber of the piston to increase rapidly to the same pressure as the lower chamber. Once the pressure is equalized, the piston quickly closes the main orifice under the push of the reset spring, stopping the flow of medium.

Features of pilot operated solenoid valve

- Adaptability to high differential pressure: Because the pilot valve acts before the main valve, it can effectively reduce the driving force required by the main valve, so the pilot solenoid valve is suitable for large differential pressure occasions, and it can control high pressure fluids.

- Precise control: through precise control of the pilot valve of the small flow can be realized on the main valve of the large flow control, thus providing more fine pressure and flow regulation.

- Energy saving and high efficiency: the use of a smaller power solenoid coil can operate a larger volume of the main valve, reducing energy consumption and improving efficiency.

Applications of pilot operated solenoid valve

- Industrial automation control: Pilot operated solenoid valves can accurately control the flow and pressure of liquids and gases to ensure the stable operation of equipment.

- Hydraulic control system: Widely used in engineering machinery, metallurgical equipment, aerospace and other fields to achieve precise control of the hydraulic system to ensure the normal operation of the machine.

- Manufacturing industry: Plays an important role in automobile manufacturing, injection molding machinery, mold manufacturing and other fields, to achieve precise control of the hydraulic system, improve production efficiency and product quality.

- Petrochemical industry: Commonly used in chemical process control, such as control of air, water, oil and other media on and off state, to ensure the normal operation of chemical equipment.

- Cleaning equipment: Widely used in the field of water supply and drainage, industrial furnaces, etc., used to control the switch of cleaning equipment to ensure the normal operation of the equipment.

- Environmental protection field: Capable of controlling the switch of filters, discharge valves and other equipment, which helps the implementation of environmental protection work.

- Other fields: Widely used in ships, agricultural machinery, wind power generation and other fields, providing reliable hydraulic control solutions for equipment in these industries.

Om DELCO Valve

DELCO-ventil is a top brand specializing in high-quality valve solutions. Our main products include a wide range of control valves,motorized valves, pneumatic valves, solenoid valves, manual valves, actuator and valve fittings. We are dedicated to offering customers reliable and efficient valve products for various industrial and commercial uses.

Hvis du har spørgsmål til ventiler eller ønsker at få et tilbud, er du velkommen til at kontakte os, vi svarer inden for 6 timer. Ring til +86 159 8960 2972, WhatsApp +86 159 8960 2972 eller e-mail marketing [email protected].