Vi giver ikke kun simple tilbud, men vi er eksperter i udvælgelse, beregning og tegning.

De bedste valg

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilotstyret magnetventil Læs mere

DELCO 2-vejs rustfrit stål pneumatiske flangekugleventiler

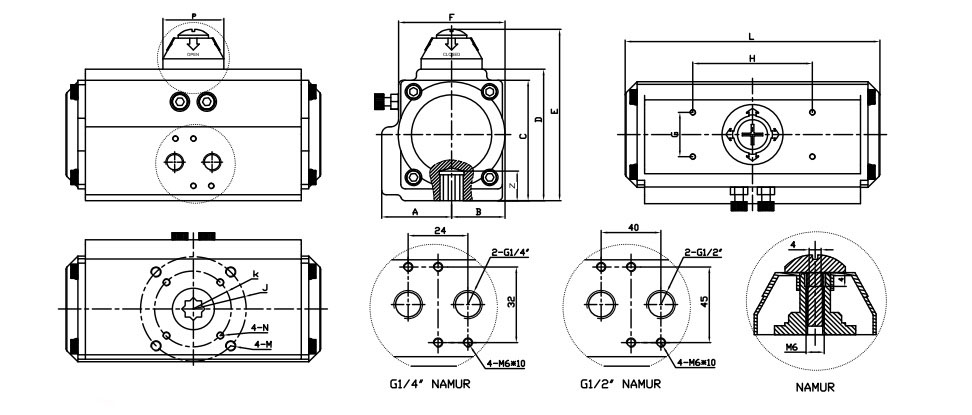

DELCO pneumatic flange ball valve is available in 2-way, 3-way, or 4-way port configurations, with a default GB standard and optional ANSI or API 6D standards. It features a double-acting standard control mode, with a single-acting option available. Constructed from 304 or 316 stainless steel, it operates with an input air pressure of 2.5 to 8 bar and has a minimum 1/2 inch flanged connection. The valve comes with a default PTFE seat, making it resistant to almost all fluids and suitable for applications with higher operating pressures and temperatures.

Model: DK66-2PF

Størrelsesområde: 1/2″ to 8″

Trykområde: 1,0 til 6,4MPa

Materiale:Rustfrit stål 304/316, WCB

DELCO DK66-2PF Pneumatic Flange Ball Valves

Tekniske parametre for ventilaktuator

| Dobbeltvirkende | Luft til at åbne, luft til at lukke, luftleverandøren har ikke holdt den aktuelle position |

| Enkeltvirkende N/C | Luft til at åbne, afbryde luft for at lukke, luft svigt i at lukke |

| Enkeltvirkende N/O | Luft til at lukke, afbryde luft til at åbne, luft manglende åbning |

| Valgfrit tilbehør | Vendemagnetventil, endestopboks, luftfilterreduktionsventil, positioner, håndtagsmanual, låseventil. |

Tekniske parametre for ventilhus

| Ventilhus | Ventilkomponenter | ||

| Størrelsesområde | DN15-DN200 | Tætningsmateriale | PTFE:-30℃~180℃ |

| Kropsmateriale | Stainless Steel, Carbon Steel,Cast iron | Core Material | Rustfrit stål |

| Tilslutningstype | Flange ( GB/ANSVDIN/JIS ) | Materiale til stilk | Rustfrit stål |

| Trykklassificering | 1.6,2.5,4.0,6.4MPa | Anvendelige medier | Control of Water, Air, Gas,Oil, Liquid, Steam |

| Struktur | Flydende kuglekerne | ||

Luftkildeprocessor: Kombinerer filtrering, trykreduktion og smørefunktioner, hvilket sikrer stabilt udgangstryk. Fås i todelte samlinger til filtrering af komprimeret instrumentluft og tredelte konfigurationer for ekstra smøring.

Pneumatisk magnetventil: Regulerer åbning og lukning af pneumatiske ventiler ved magnetisering og afmagnetisering til direkte gasstrøm baseret på spændingssignaler. Tilbyder præcis kontrol over ventiloperationer, der almindeligvis anvendes til styring af gaskilde og kredsløbsflow.

Grænseafbryder: Registrerer ventilstatus og udsender signaler for åbne eller lukkede positioner. Kritisk i automatiske kontrolsystemer, bekræftelse og udførelse af efterfølgende programmer, sikring af ventilspærring og indikering af fjernalarmer i systemet.

Ventilpositioner: Afgørende for præcis kontrol over ventilpositionering i pneumatiske kontrolventiler, sammenligning af ventilspindelforskydning og controllerudgangssignaler, justering af aktuatorudgangssignalet i overensstemmelse hermed.

Manuel enhed: Komplementerer pneumatiske aktuatorsamlinger, hvilket letter manuel eller pneumatisk betjening af butterfly- og kugleventiler med en 90° åbning. Sikrer alsidighed og fleksibilitet i ventildrift, hvilket giver mulighed for manuel og automatiseret kontrol efter behov.

Få et hurtigt tilbud

ANBEFALER

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilotstyret magnetventil Læs mere

Få et hurtigt tilbud

ANBEFALER

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilotstyret magnetventil Læs mere