BLOG

DELCO Valve Provide Various Optimal Solution For Industrial Valves, Especially For Control Valves.

TAGS

Contact Us

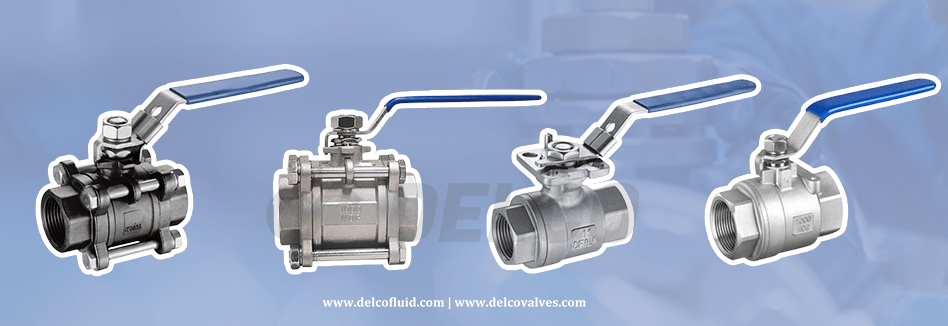

Comparison between 2PC Ball Valve and 3PC Ball Valve

- DELCO Valve

Choosing the right ball valve is very important for any plumbing or industrial project. DELCO has ball valve products suitable for various industrial applications, and understanding the differences between 2pc and 3pc ball valves can help you make the right decision. Let’s take a look at the comparison between these two ball valves.

What is a 2-Piece Ball Valve?

2-Piece Ball Valves are connected by two separate components, either threaded connections or bolted and flanged assemblies. These components have a valve body and end connections. They can be easily disassembled for maintenance or repair. This design offers flexibility and ease of repair, and is popular in industrial environments where frequent maintenance is required. However, because two separate parts are connected, the potential for leakage exists and it is not suitable for high pressure applications.

What is a 3- Piece Ball Valve?

3- Piece Ball Valves have a main body and two pipe connectors. The piping connectors are welded or threaded to the piping. Because of its three-piece construction, it can be easily assembled and disassembled without cutting the piping. making it ideal for industries such as oil and gas, chemical processing and water treatment. However, it is also more expensive than two-piece ball valves due to the complexity of its construction. The additional components and assembly complexity result in higher costs. Despite the cost factor, the benefits of easy installation and maintenance make the 3pc ball valve the preferred choice for industries requiring frequent repairs and system modifications.

2-Piece & 3-Piece Ball Valve Comparison

2-Piece Ball Valves | 3-Piece Ball Valves | |

Advantages

|

|

|

Disadvantages

|

|

|

Common Applications |

|

|

Factors to consider when selecting a ball valve

- Size: Make sure the valve size meets the requirements of your system.

- Material: Select a material based on factors such as corrosion resistance and durability.

- Pressure Rating: Select a valve that can handle the pressure rating of your application.

- Application: Consider the specific needs of your project or industry.

Conclusion

The selection of a ball valve depends on key factors such as project-specific needs, maintenance considerations and cost effectiveness. DELCO not only offers ball valves, but also provides solutions to suit the changing needs of the modern industrial sector. Our product range includes 2pc ball valves, 3pc ball valves and various other customizable options.

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.