BLOG

DELCO Valve Provide Various Optimal Solution For Industrial Valves, Especially For Control Valves.

TAGS

Contact Us

Comprehensive Guide to Ball Valves

- Morning Jiang

Ball valves are essential components in various piping systems, utilized for their reliability and efficiency in controlling fluid flow. This guide explores the three main types of ball valves: 1 Piece, 2 Piece, and 3 Piece constructions, highlighting their features, advantages, and applications.

1 Piece Ball Valve

Overview

1 Piece ball valves feature a single body into which the ball, stem, and seals are inserted from one end and secured by an end insert. This design is commonly found in low-cost mass-produced brass ball valves, ideal for light-duty isolation.

Key Features

- Construction: Made from a single piece, which enhances durability.

- Flow Characteristics: Typically designed as a reduced bore ball valve, the bore through the ball is smaller than that of the connecting pipes, restricting flow.

Applications

1 Piece ball valves are suitable for applications where cost is a significant factor and where flow restrictions are acceptable. Commonly used in residential plumbing and light industrial applications.

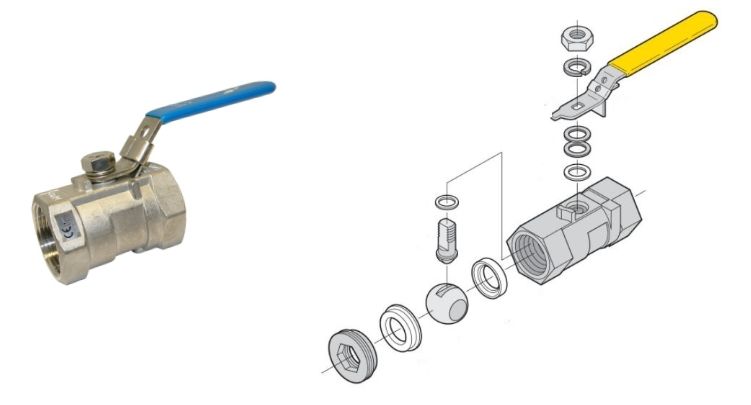

2 Piece Ball Valve

Overview

2 Piece ball valves consist of a split body design that accommodates a larger ball. This allows for a bore through the ball that matches the bore of the connecting pipe, facilitating smooth, unrestricted flow—commonly referred to as a full bore ball valve.

Key Features

- Construction: Comprises two body pieces, typically screwed together for threaded connections or bolted for flanged connections.

- Flow Characteristics: The full bore design ensures minimal pressure drop and optimal flow efficiency.

Applications

2 Piece ball valves are ideal for industrial applications where maintaining high flow rates is crucial, such as in water treatment facilities and chemical processing plants.

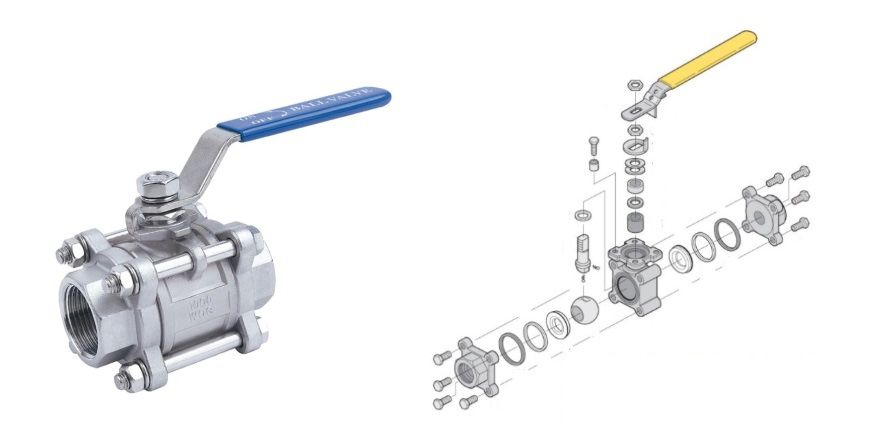

3 Piece Ball Valve

Overview

3 Piece ball valves feature a center section body into which the ball is installed, ensuring a bore that matches the connecting pipe for unrestricted flow. The design includes individual end pieces that are bolted to the center section.

Key Features

- Maintenance: A significant advantage of the 3 Piece design is that the center section can be removed without disturbing the end connections, allowing for in-line maintenance.

- Material Variety: Commonly available in CF8M cast stainless steel, these valves can be manufactured from various materials to suit different applications.

Applications

3 Piece ball valves are often used in demanding environments where maintenance accessibility is vital, such as in oil and gas, pharmaceuticals, and food processing industries.

Conclusion

Understanding the different types of ball valves—1 Piece, 2 Piece, and 3 Piece—enables you to select the right valve for your application. Each type offers unique benefits suited for specific industrial needs, from cost-effective solutions to high-performance options. Proper selection and maintenance of these valves ensure efficient operation and longevity in your piping systems.

For more information about our selection of ball valves and other flow control products, please visit our website.