BLOG

DELCO Valve Provide Various Optimal Solution For Industrial Valves, Especially For Control Valves.

TAGS

Contact Us

Knife Gate Valve Features

- DELCO Valve

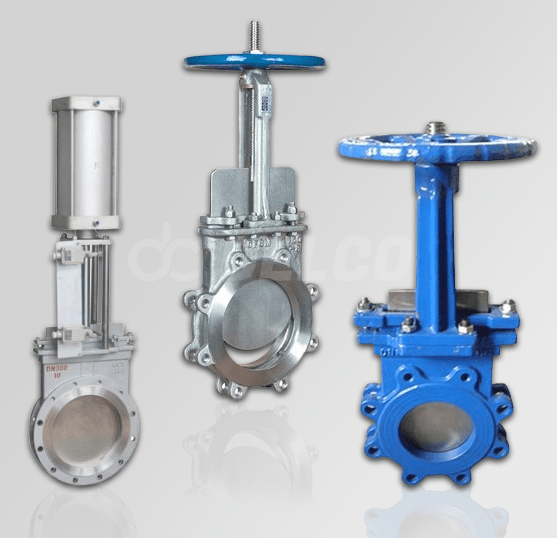

In industrial piping systems, knife gate valves are favored for their unique design and superior performance. Below is an overview of the main features of knife gate valves by DELCO.

What is a knife gate valve?

Knife gate valves, similar in design to gate valves, initially found application in the pulp and paper industry. These valves are adept at handling dense, particulate-filled fluids where traditional valves might struggle to seal tightly, leading to potential leaks.

In operation, knife gate valves function by raising a plate with a flat or “knife” edge to obstruct the flow path, allowing it to navigate through obstacles during closure for a secure seal on a soft sealing surface. This type of seal is suitable for lower pressure systems and isn’t intended for high-pressure environments. Knife gate valves excel in providing isolation or on/off functionality rather than precise flow control or modulation.

Knife gate valve features:

- Short Structure Length: the knife gate valve adopts short structure design to save material and space during installation and effectively ensure the strength of pipeline.

- Easy Installation: the knife gate valve is designed for easy installation, is wear-resistant and has an anti-clogging function for long-lasting stability.

- Easy Maintenance: the valve is easy to maintain, ensuring a convenient maintenance process, and its structure and materials ensure a long service life.

- Lifted Gate Sealing Surface: The valve utilizes a lifting gate sealing surface that automatically removes debris and effectively removes adherents.

- Full-Circle Straight-Through Passage Design: This design prevents residue buildup and ensures unobstructed piping.

- Adjustable V-gate: The V-gate design allows for adjustable flow, providing flexible control options.

- Durable Stainless Steel Body: The valve body is made of corrosion-resistant stainless steel for added strength and features double-head screws for quick operation.

- Material-Saving Bracket Design: Triangular bracket design effectively saves material while maintaining mechanical properties.

- Multiple Drive Modes: choose the appropriate drive mechanism according to the working conditions.

- Anti-corrosive Material: completely made of stainless steel to prevent corrosion damage, with different materials such as 304, 316, 316L, WCB and corrosion-resistant seals for choice.

Why choose DELCO?

DELCO Valve is a leading global manufacturer specializing in valves, boasting 20 years of rich industry experience. Originating from German technology, DELCO has its own dedicated teams for research and development, design, production, and sales, with a vision to become a premier provider of automatic applications worldwide.

- Customization Capability: DELCO excels in offering tailored solutions to meet individual customer needs, ensuring optimum performance and efficiency across various industries.

- Quality Control: The DELCO factory enforces strict quality control measures at every stage of the manufacturing process to uphold exceptional standards.

- After-Sales Support: DELCO prides itself on providing outstanding after-sales assistance, including technical support, maintenance services, and readily available spare parts.

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].