BLOG

DELCO Valve Provide Various Optimal Solution For Industrial Valves, Especially For Control Valves.

TAGS

Contact Us

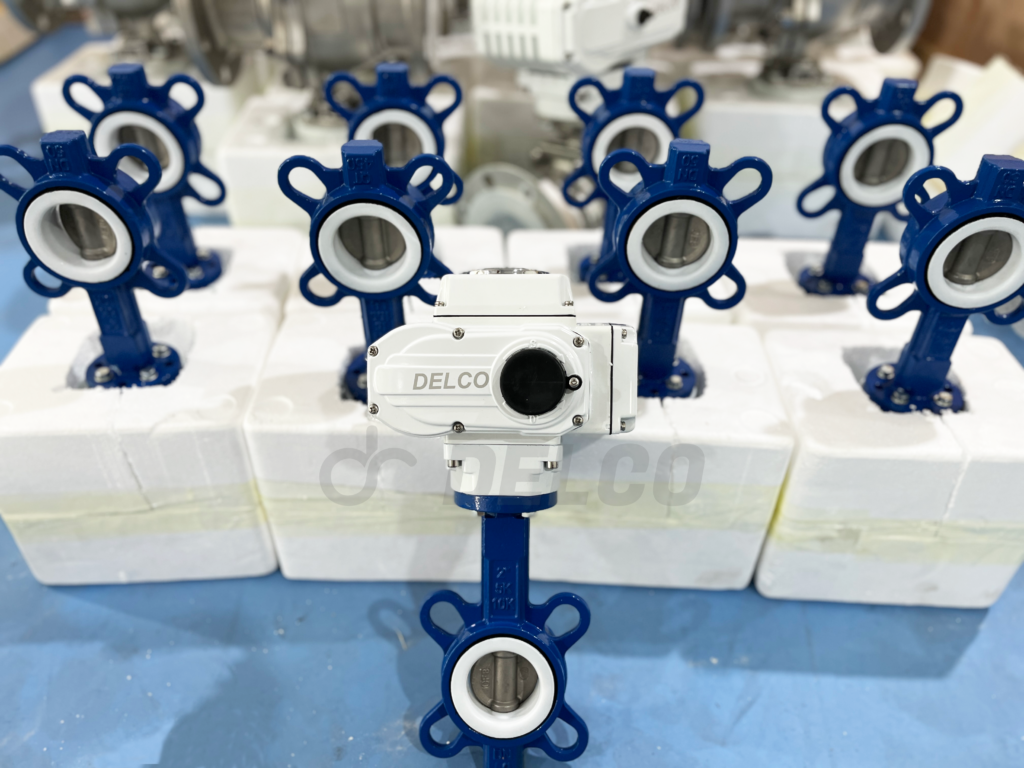

Motorized Wafer Butterfly Valve: Features and Applications

- DELCO Valve

Motorized wafer butterfly valve is a common industrial valve with unique design and various uses. Let’s take a look at the features and applications of this type of valve.

What is a motorized wafer butterfly valve

The motorized butterfly valve is a type of valve that turns a quarter when operated by an electric actuator. It is used to regulate the flow of substances in pipelines. Wafer type butterfly valve is one of the common types of butterfly valves. Typically, wafer butterfly valves are designed with four holes that match up with the pipeline they are connected to. This valve is intended to be clamped between two flanges in your pipeline system. Most wafer butterfly valves are compatible with the majority of flange standards. The rubber or EPDM valve seat ensures a strong seal between the valve and the flange connection.

How a wafer butterfly valve works

Regardless of how they are activated, all wafer butterfly valves serve the same purpose—to allow, stop, or control the flow of liquids or semi-solids.

When you turn the valve handle counterclockwise a quarter of a turn, the stem and disc also turn, aligning the disc with the fluid flow to halt it. Rotating the handle clockwise for a quarter turn positions the disc perpendicular to the flow, allowing the fluid to pass through.

To close a wafer butterfly valve, you turn the handle clockwise, causing the disc to rotate and become perpendicular to the pipe. When the disc contacts the seat, the valve is fully closed, stopping the fluid flow.

Features of motorized wafer butterfly valve

- Compact structure: the valve adopts a new structural design, more lightweight and easy to install, easy to maintain.

- Energy efficient: smooth circulation, low energy consumption, stable operation.

- Reliable and durable: simple structure, long service life, stable performance.

- Multifunctional installation: suitable for different media, flexible installation.

Application areas of motorized wafer butterfly valve

- Chemical and building materials: used in ventilation and environmental protection projects, regulating gas flow.

- Power station and glass: operating in a high-temperature environment, stable control of media flow.

- Metallurgy and mining: handling temperature does not exceed 300 ℃ medium, for pipeline control.

Conclusion

Motorized wafer butterfly valve plays an important role in modern industry, providing reliable solutions for fluid control. In these industrial processes, DELCO’s wafer butterfly valves have demonstrated outstanding performance and reliability. No matter what kind of butterfly valve you need, we can provide professional customization services and technical support.

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].