We don’t just provide simple quotations, but we are experts in selection, calculation and drawing.

Top Picks

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more

DELCO Cast Iron Multi Turn Wafer Electric Butterfly Valves

The Multi Turn Wafer Electric Butterfly Valves is primarily utilized for powder material hoppers and switch boxes, serving as an effective solution for managing powdery or granular materials within silos. It is suitable for all types of powdery and granular materials, employing gravity closure material valves and pneumatic transmission. These valves can be installed in dry material hoppers, bins, silos, or beneath various types of spiral conveyors, and they can also connect with pneumatic conveying pipelines. Due to their specialized structure and the use of engineering materials, Multi Turn Wafer Electric Butterfly Valves are always a very economical and efficient choice.

Model: Multi Turn Wafer Electric Butterfly Valve

Size Range: 2” to 40”

Pressure Range: 1.6-6.4Mpa

Material: Cast Iron or Stainless Steel 304/316

Multi Turn Wafer Motorized Butterfly Valve

Multi-turn electric valves find significant applications across industries such as electric power, metallurgy, petroleum, chemical engineering, paper-making, and sewage disposal. These actuators are crucial for controlling gate valves, ensuring efficient operation of various industrial processes.

Applications in Different Industries

- Electric Power: Regulating water and steam flows in power plants to maintain efficiency and safety.

- Metallurgy: Controlling the flow of metals and gases in metallurgical processes for optimal conditions.

- Petroleum: Precisely managing crude oil and natural gas flows in refineries and pipelines for safe and efficient processing.

- Chemical Engineering: Handling chemical flows to maintain process integrity and safety in chemical plants.

- Paper-Making: Regulating the flow of liquids and chemicals for consistent quality in paper production.

- Sewage Disposal: Managing wastewater flow for effective treatment and disposal in sewage treatment facilities.

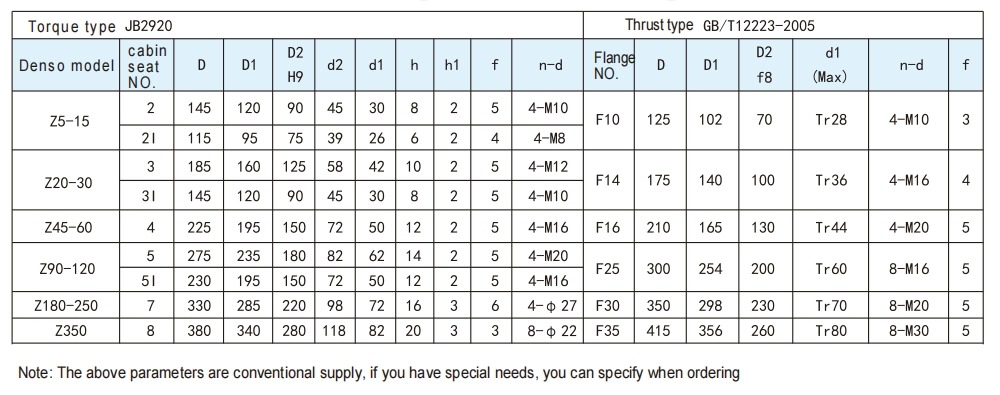

Technical Parameters of Multi-turn Actuator

| Power supply | general: single-phase 220v, three-phase 380v(50Hz), long distance DC24V |

| special: single-phase 110v, three-phase 415v, 660v(50Hz, 60Hz) | |

| Working environment | Ambient temperature: -20 ~ + 60 ℃ (special temperature environment can be customized) |

| Relative humidity: 95% (at 25 ° C) | |

| The outdoor type can be used in the places without inflammable / explosive and corrosive medium | |

| d I | applicable to non-excavating workinarea for coal mine |

| d I BT4 | applicable to the environment with IIA , IIB grade TL-T4explosive gas mixture , can be used in the factory |

| Protection level | Outdoor type and explosion-proof type are IP55 (IP65, IP67) |

| Working time | short time 10 minutes (15-60 minutes for special order) |

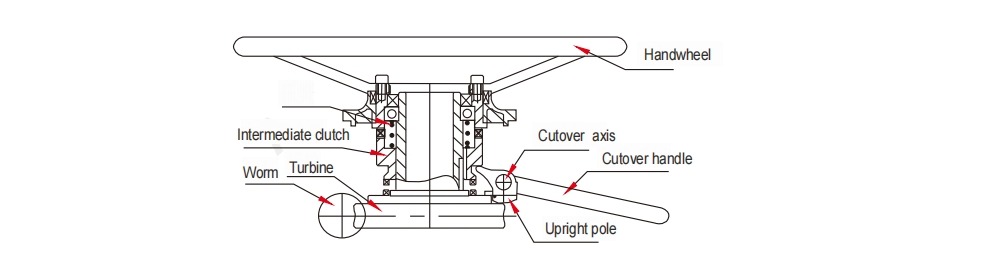

Multi-turn valve electric actuator Connection size

Get A Quick Quote

RECOMMEND

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more

Get A Quick Quote

RECOMMEND

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more