We don’t just provide simple quotations, but we are experts in selection, calculation and drawing.

Top Picks

-

DELCO Stainless Steel Pilot Operated Piston Pressure Reducing Valves

Pressure Reducing Valve Read more

DELCO Self-Operated Nitrogen Sealing Control Valves

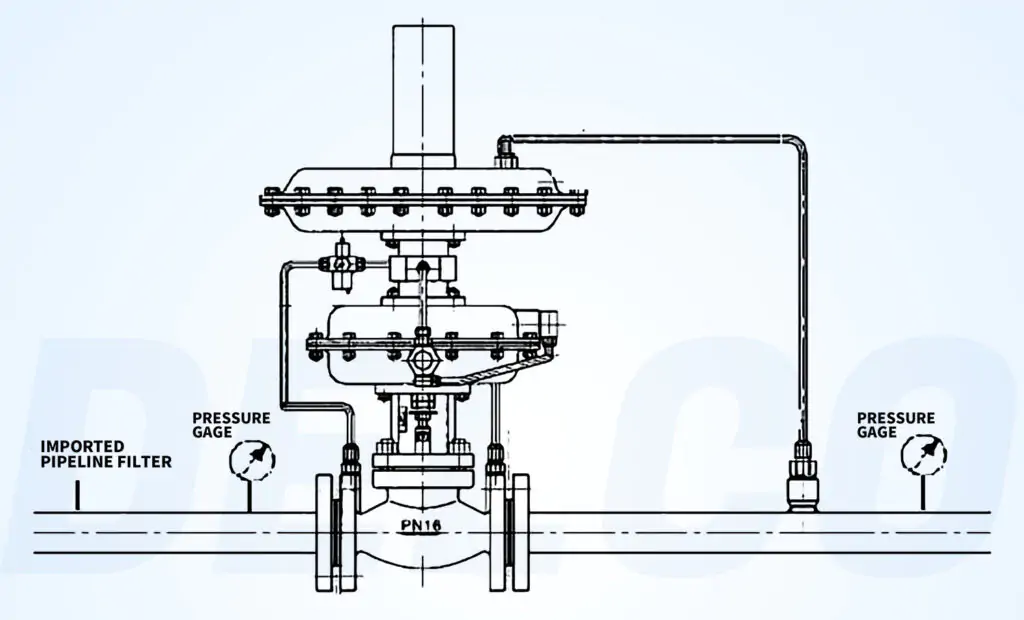

The ZZYVP type commander operates the self-operated pressure regulating valve (nitrogen sealing valve), an energy-efficient valve that automatically adjusts and stabilizes pressure without external energy. Pressure setting is conveniently and rapidly done on the commander, allowing for on-the-fly adjustments during operation. With twice the precision of ordinary self-operated pressure regulating valves, it’s ideal for precision control needs. Widely used in chemical, petroleum, metallurgy, electric power, textile, and other industries for process automation.

Model: Self-Operated Nitrogen Sealing Control Valve

Size Range: 1/2”~4′

Pressure Range: PN16~PN100

Material: WCB, 304

Introduction to Self-Operated Nitrogen Sealing Control Valves:

The self-operated nitrogen sealing valve serves to maintain a constant nitrogen pressure atop storage tanks, safeguarding stored materials and ensuring tank safety. It consists of two main components: a quick release valve and a self-operated micro pressure regulating valve.

Here’s how it works:

- When the tank pressure exceeds the set threshold, the quick release valve promptly opens, releasing excess pressure.

- Conversely, as tank pressure decreases, the micro pressure regulating valve opens, replenishing the tank with nitrogen gas.

- However, operational constraints require the micro pressure regulating valve to operate at pressures below atmospheric. Thus, a separate pressure regulating valve is needed to lower the pressure before its application.

This system has a nominal pressure rating of 0.1 MPa and allows for adjustable pressure settings ranging from 0.5 kPa to below 66 kPa. Additionally, it can handle medium temperatures of up to 80°C.

Technical Parameters:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Autonomy: Self-operated pressure control valves require no external power sources or complex control systems, relying solely on the pressure of the fluid itself to regulate flow rates and maintain pressure levels, reducing reliance on external infrastructure and enhancing system reliability.

Efficiency: By automatically adjusting flow rates in response to changes in pressure, self-operated valves help optimize energy usage and reduce operating costs in fluid-based systems.

Reliability: With their robust design and self-regulating mechanism, self-operated pressure control valves offer reliable performance in a wide range of operating conditions, ensuring stable pressure control and system safety.

Flexibility: Self-operated pressure control valves are highly adaptable and can be customized to meet the specific requirements of different applications, making them suitable for a variety of fluid control tasks.

Self-Operated Pressure Control Valves Applications:

The versatility and autonomy of self-operated pressure control valves make them indispensable in a variety of applications across different industries. Some common applications include:

Steam Systems: These valves are widely used in steam distribution systems to regulate steam pressure and ensure consistent performance in heating, sterilization, and other processes.

Oil and Gas Production: In the oil and gas industry, self-operated pressure control valves play a crucial role in controlling pressure levels in production wells, pipelines, and processing facilities, ensuring safe and efficient operations.

Water Distribution Networks: Self-operated pressure control valves are used in water distribution networks to maintain optimal pressure levels in municipal water supply systems, preventing water hammer and ensuring reliable water delivery to consumers.

Get A Quick Quote

RECOMMEND

-

DELCO Stainless Steel Pilot Operated Piston Pressure Reducing Valves

Pressure Reducing Valve Read more

Get A Quick Quote

RECOMMEND

-

DELCO Stainless Steel Pilot Operated Piston Pressure Reducing Valves

Pressure Reducing Valve Read more