We don’t just provide simple quotations, but we are experts in selection, calculation and drawing.

Top Picks

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more

DELCO Stainless Steel Lug Style Spring Return Pneumatic Butterfly Valves

The air actuated butterfly valves, featuring a lug body design, offers versatility with the option for either a spring return actuator or a double-acting actuator. Its seals are compatible with air, water, oil, and other media that align with the materials of construction.

Classified by sealing performance, pneumatic butterfly valves can be categorized into metal seal and soft seal types. Advantages of pneumatic butterfly valves over other types of valves may encompass their compact structure, small size, extended service life, reliable sealing capabilities, ease of maintenance, and quick detachable and installation features.

Model: DK67-LB-S

Size Range: 2”~16”

Pressure Range: 1.0MPa to 1.6MPa

Material: Stainless Steel 304/316

DELCO Lug Style Spring Return Air Actuated Butterfly Valve

The LT type, also known as the single plate butterfly valve or lug type butterfly valve, is a straightforward regulating valve design. It’s particularly suitable for low-pressure pipeline applications where the closing element, typically a disk or butterfly plate, rotates around the valve shaft to control the flow by opening and closing.

This type of valve finds utility across various fluid types, including air, water, steam, corrosive media, mud, oil products, and liquid metals. In pipelines, its primary function is to cut off or throttle the flow. The butterfly valve operates with a disc-shaped butterfly plate, pivoting around its axis within the valve body to regulate the flow or completely shut it off.

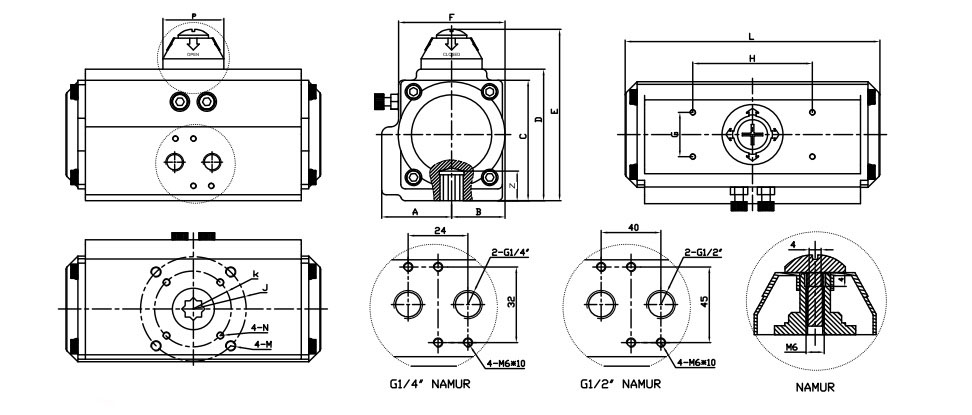

Technical Parameters of Valve Actuator

| Double acting | Air to open, air to close, air supplier failure to keep the current position |

| Single acting N/C | Air to open, interrupt air to close, air failure to close |

| Single acting N/O | Air to close, interrupt air to open, air failure to open |

| Optional accessory | Reversing solenoid valve, limit switch box, air filter reducing valve, positioner, handle manual, lock up valve. |

Technical Parameters of Valve Body

| Body | Valve components | ||

| Size range | DN50~DN400 | Sealing material | PTFE, PPL, NBR |

| Body material | Stainless Steel | Core material | Stainless steel |

| End conection | Wafer Flange | Stem material | Stainless steel |

| Operating pressure | 1.0MPa 1.6MPa | Applicable media | Control of Water, Air, Gas,Oil, Liquid, Steam |

| Structure | Midline Structure/ A-type | ||

Air source processor: Combines filtering, pressure reduction, and lubrication functions, ensuring stable outlet pressure. Available in two-piece assemblies for filtering compressed instrument air and three-piece configurations for added lubrication.

Pneumatic solenoid valve: Regulates the opening and closing of pneumatic valves by magnetizing and demagnetizing to direct gas flow based on voltage signals. Offers precise control over valve operations, commonly used for managing gas source and circuit flow.

Limit switch: Detects valve status and outputs signals for open or closed positions. Critical in automatic control systems, confirming and executing subsequent programs, providing valve interlock protection, and indicating remote alarms within the system.

Valve positioner: Crucial for precise control over valve positioning in pneumatic control valves, comparing valve stem displacement and controller output signals, adjusting the actuator output signal accordingly.

Manual device: Complements pneumatic actuator assemblies, facilitating manual or pneumatic operation for butterfly and ball valves with a 90° opening. Ensures versatility and flexibility in valve operation, allowing for manual and automated control as needed.

Get A Quick Quote

RECOMMEND

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more

Get A Quick Quote

RECOMMEND

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more