We don’t just provide simple quotations, but we are experts in selection, calculation and drawing.

Top Picks

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more

DELCO Stainless Steel Piston Flange Pneumatic Angle Seat Ball Valve

The pneumatic Pneumatic Angle Seat Ball Valve is extensively utilized in beer and beverage canning lines, printing and dyeing textiles, the gas industry, pharmaceutical and medical equipment, the chemical industry, high-temperature sterilization, foaming machinery, water treatment equipment, and more.

The pneumatic angle seat valve is ideal for applications requiring frequent short-term start-ups, offering quick response and precise operation. When paired with a solenoid valve, pneumatic control can precisely regulate the flow of gases and liquids, meeting the demands for accurate temperature control and liquid dispensing. Additionally, angle seat valves are used to control steam quantities and ensure precise temperature management in moist heat sterilization cabinets.

Model: Pneumatic Angle Seat Flange Valve

Size Range: 1/2”~4”

Pressure Range: 0~2.5 MPa

Material: Stainless Steel 304/316

DELCO Pneumatic Flange Angle Seat Ball Valve

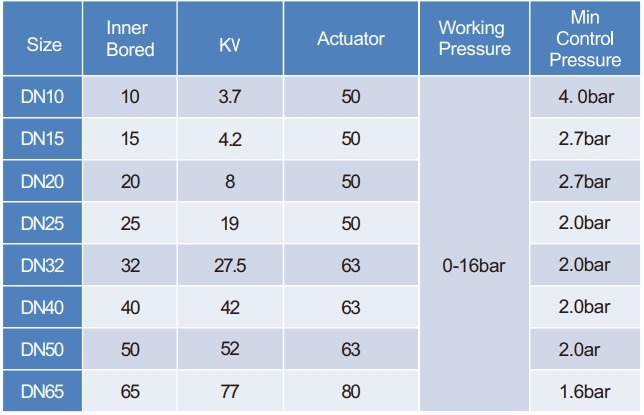

Technical Parameters of Valve Body

| Actuator material | Stainless steel or PolyamidePA | Body material | SS304, 316, 316L |

| Seat material | PTFE, F46 | Stem material | SS304, 316, 316L |

| Ambient temp | -30℃~180℃ | Pressure | 0~2.5 MPa |

| Connection Type | Flange, thread, welding, clamp | Control type | Single-acting, double-acting |

| Applicable medium | Water, natural gas or liquid alcohol, oil, organic solvent, steam | Optional accessory | Solenoid valve, limit switch box, positioner, etc |

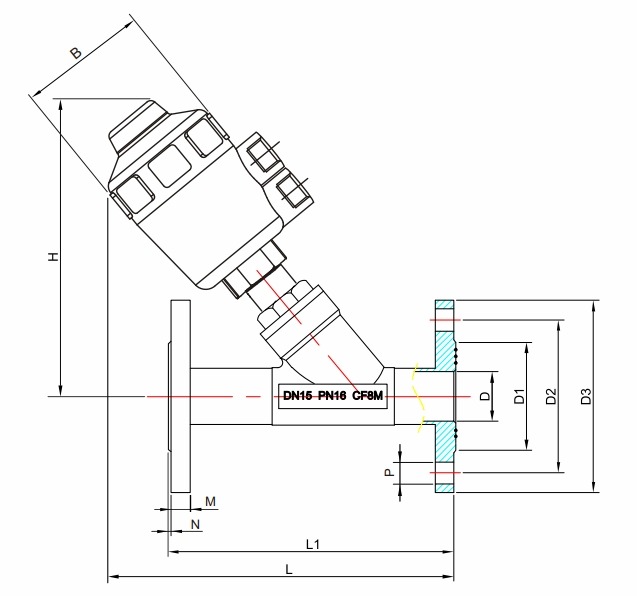

Flange Pneumatic Angle Seat Valve

| Size | Inch | D | D1 | D2 | D3 | B | M | N | L1 | L | H | P |

| DN15 | 1/2″ | 16 | 45 | 65 | 95 | 64 | 14 | 2 | 120 | 180 | 137 | 4 -∅14 |

| DN20 | 3/4″ | 20 | 56 | 75 | 105 | 64 | 14 | 2 | 130 | 185 | 145 | 4 -∅14 |

| DN25 | 1″ | 25 | 65 | 85 | 115 | 80 | 14 | 3 | 140 | 210 | 173 | 4 -∅14 |

| DN32 | 1/1/4″ | 32 | 78 | 100 | 140 | 80 | 16 | 2 | 150 | 240 | 210 | 4 -∅18 |

| DN40 | 1-1/2″ | 39 | 84 | 110 | 150 | 80 | 16 | 3 | 180 | 245 | 260 | 4 -∅18 |

| DN50 | 2″ | 50 | 100 | 125 | 165 | 100 | 16 | 3 | 195 | 295 | 300 | 4 -∅18 |

| DN65 | 2/1/2″ | 66 | 120 | 145 | 185 | 126 | 18 | 3 | 230 | 320 | 315 | 4 -∅18 |

| DN80 | 3″ | 80 | 135 | 160 | 200 | 126 | 18 | 3 | 250 | 330 | 330 | 8-∅18 |

| DN100 | 4″ | 100 | 155 | 180 | 215 | 126 | 18 | 4 | 280 | 360 | 350 | 8- ∅18 |

Get A Quick Quote

RECOMMEND

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more

Get A Quick Quote

RECOMMEND

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Pilot Operated Solenoid Valve Read more