No nos limitamos a ofrecer simples cotizaciones, sino que somos expertos en selección, cálculo y dibujo.

Las mejores selecciones

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Electroválvula pilotada Leer más

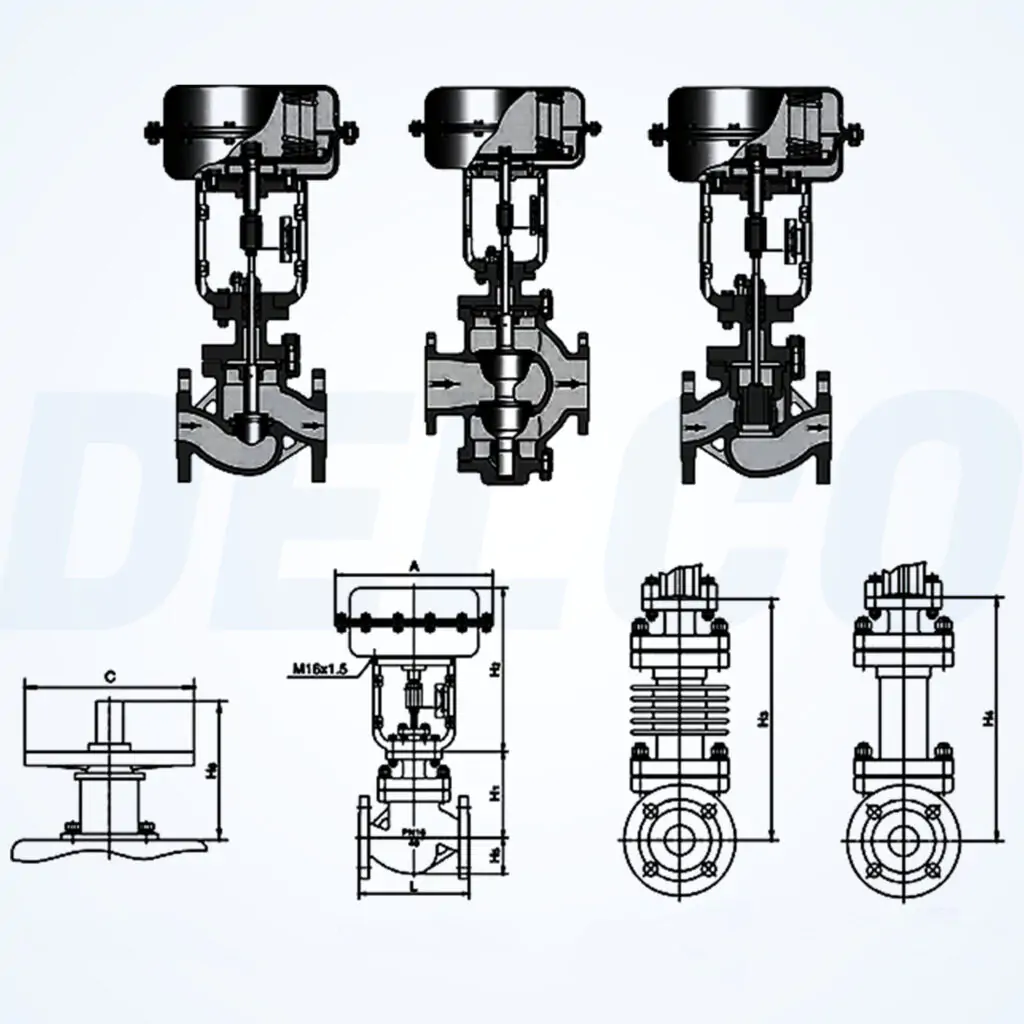

DELCO DN25 PN16 WCB Threaded Pneumatic Control Valve

DELCO Pneumatic control valve possesses a low center of gravity, exceptional vibration resistance, and simple installation procedures. These valves are widely employed in automated production control systems in industries like chemistry, petroleum, light industry, power stations, and metallurgy. DELCO Valve is committed to providing our clients with premium items at competitive rates, guaranteeing prompt delivery and comprehensive warranty coverage.

Modelo: ZJHP

Rango de tallas: 1/2”~12′

Rango de presión: 1.6~6.4Mpa

Material: WCB, Stainless Steel 304, 316, 316L

Introduction to Pneumatic Control Valves:

Pneumatic control valves are a key device used to control the flow of fluid media with precise regulation and fast response characteristics. These valves usually use pneumatic actuators to drive the opening and closing of the valve through the pressure of a gas such as air or nitrogen, thus realizing the control of flow, pressure or temperature.

Pneumatic control valves are widely used in automated production control systems in various industrial fields such as chemical, petroleum, electric power, metallurgy and so on. Its low center of gravity design gives it good stability, and its high vibration resistance ensures stable operation under harsh working conditions. Easy installation and simple maintenance make pneumatic control valves an indispensable key component in industrial automation control systems.

DELCO Valve is committed to providing customers with high quality pneumatic control valves at the most competitive prices, ensuring timely delivery and providing comprehensive after-sales service. Our pneumatic control valves not only have the advantages of high reliability and stable performance, but also can meet the precise control requirements in different industrial application scenarios.

Introduction to Pneumatic Control Valves:

| Tipo | Presión nominal | Estructura | Cooling type | Packing |

| Single-seat, double-seat, sleeve | PN16, PN25, PN40, PN64 | Standard type (-20℃ ~+200℃ ) |

(-40~450℃ ) | V type PTFE, flexible graphite |

| Diámetro nominal | Conexión | Material | Low-temperature type | Adjustable range |

| DN15-DN300 | Flange, thread, weld (Or other customer specified) |

WCB, 304, 316, 316L | (-60℃ ~-196℃ ) | 50:1 |

| Sealing surface | Basic error | Accessories | Leakage class | |

| PN16 convex surface, PN40, PN63, PN100 | Less than full stroke +-1% (With locator) Less than full | locator, air filter pressure-relief valve, hand wheel device, limit switch, solenoid valve, lock up valve, and others. | Metal seal: Less than 0.01 (ANSI B16.104-1976IV) | Soft seal: Less than 0.00001% |

Valve Components: Features a single-seat plunger core design with a 304 or 316+ SLT core seat, offering equal percentage, linear, and quick-opening flow characteristics.

Valve Actuator: Utilizes a multi-spring diaphragm actuator available in both direct and reverse actions. The diaphragm is made from NBR rubber reinforced with polyester fabric. The spring ranges include 20-100 KPa, 40-200 KPa, and 80-240 KPa, with supply pressures ranging from 0.4 MPa to 0.5 MPa.

Action Type: For air-to-close (FO) operation with a direct action actuator, the actuator spring opens the valve when the air supply fails. For air-to-open (FC) operation with a reverse action actuator, the actuator spring closes the valve when the air supply fails. Provides linear, equal percentage, and quick-opening characteristics.

When selecting a control valve, consider the following factors:

Flow requirements: Evaluate the flow characteristics needed for the specific application.

Flow Characteristics: Consider the fluid’s properties, such as viscosity, pressure, and temperature, to select a valve that can handle the specific conditions.

Valve size: Choose a valve size that matches the pipeline size and meets the required flow capacity.

Actuator type: Decide between manual, electric, pneumatic, or hydraulic actuation based on the system requirements and available resources. Select an actuator that provides adequate force and meets the desired control requirements.

Material compatibility: Ensure the valve materials are compatible with the fluid being handled to avoid corrosion or other damage.

Regulatory requirements: Adhere to industry-specific regulations and standards to ensure safe and efficient operation.

Noise and vibration: Option for a valve design that minimizes noise and vibration for a safer, more reliable operation.

Obtenga una cotización rápida

RECOMENDAR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Electroválvula pilotada Leer más

Obtenga una cotización rápida

RECOMENDAR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Electroválvula pilotada Leer más