We don’t just provide simple quotations, but we are experts in selection, calculation and drawing.

Las mejores selecciones

-

DELCO Stainless Steel Pilot Operated Piston Pressure Reducing Valves

Válvula reductora de presión Leer más

DELCO Stainless Steel T Type Pneumatic Actuated Drum Piston Valves

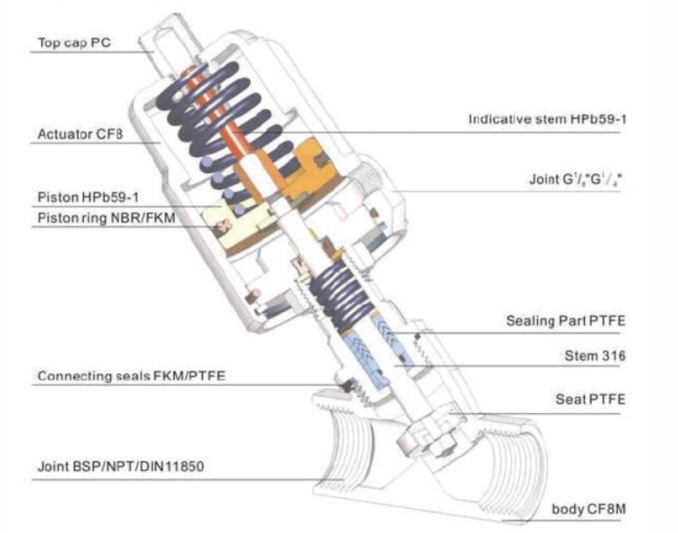

This innovative angle seat valves operates with a two-position, two-way pneumatic piston design, featuring low starting pressure and high sensitivity for closing. It excels in sealing performance, guaranteeing no water leakage. This valve is widely employed across industries including food processing, textiles, pharmaceuticals, industrial laundry equipment, and the chemical industry.

Modelo: Pneumatic angle seat valves

Rango de tallas: 1/2”~2”

Rango de presión: 0~1.6 MPa

Material: Acero inoxidable 304/316

High Flow Compact Pneumatic Control Angle Seat Valve with NPT Thread

Types and Working Principles

Key features include:

- High Flow Rate: Ensures efficient operation for demanding applications.

- NPT Thread Connection: Provides a secure and reliable connection.

- Position Indicator: Offers clear visual feedback on valve status.

- 360° Rotatable Pilot Connection: Allows for flexible installation options.

- Durable Construction: Designed for a high cycle life, outperforming traditional ball valves.

This valve is ideal for applications requiring reliable and efficient pneumatic control, with customizable configurations to meet specific needs.

Parámetros técnicos del cuerpo de la válvula

| Actuator material | Stainless steel or PolyamidePA | Body material | SS304, 316, 316L |

| Seat material | PTFE, F46 | Stem material | SS304, 316, 316L |

| Ambient temp | -30℃~180℃ | Pressure | 0~1.6MPa |

| Conncetion Type | Flange, thread, welding, clamp | Control type | Single acting, double acting |

| Applicabl medium | Water, netural gas or liquid allohol, oil, organic solvent, steam | Optional accessory | Solenoid valve, limit switch box, positioner, etc |

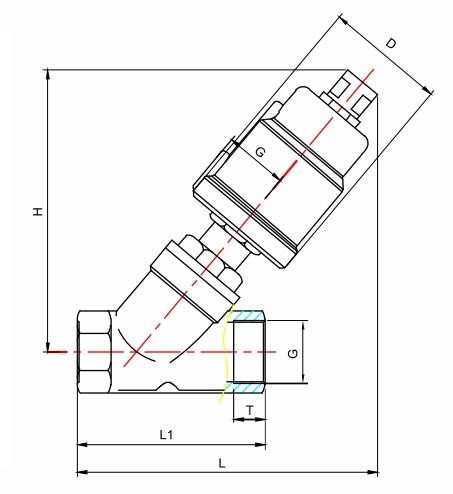

Thread Angle Seat Valves

| Size | D | L | L1 | H | D | R | T | Weight |

| DN15 | 1/2″ | 133 | 68 | 126 | 62 | 33 | 11 | 1.1 |

| DN20 | 3/4″ | 137 | 75 | 131 | 62 | 33 | 14 | 1.2 |

| DN25 | 1″ | 151 | 90 | 142 | 62 | 33 | 15 | 2.2 |

| DN32 | 1-1/4″ | 188 | 115 | 175 | 76 | 42 | 17 | 2.7 |

| DN40 | 1-1/2″ | 190 | 115 | 175 | 76 | 42 | 17 | 4.8 |

| DN50 | 2″ | 205 | 135 | 195 | 76 | 42 | 20 | 6.8 |

Obtenga una cotización rápida

RECOMENDAR

-

DELCO Stainless Steel Pilot Operated Piston Pressure Reducing Valves

Válvula reductora de presión Leer más

Obtenga una cotización rápida

RECOMENDAR

-

DELCO Stainless Steel Pilot Operated Piston Pressure Reducing Valves

Válvula reductora de presión Leer más