Kami bukan sahaja menyediakan sebut harga yang mudah, tetapi kami pakar dalam pemilihan, pengiraan dan lukisan.

Pilihan Teratas

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

DELCO Stainless Steel 2 Way High Pressure Pneumatic Actuated Ball Valves

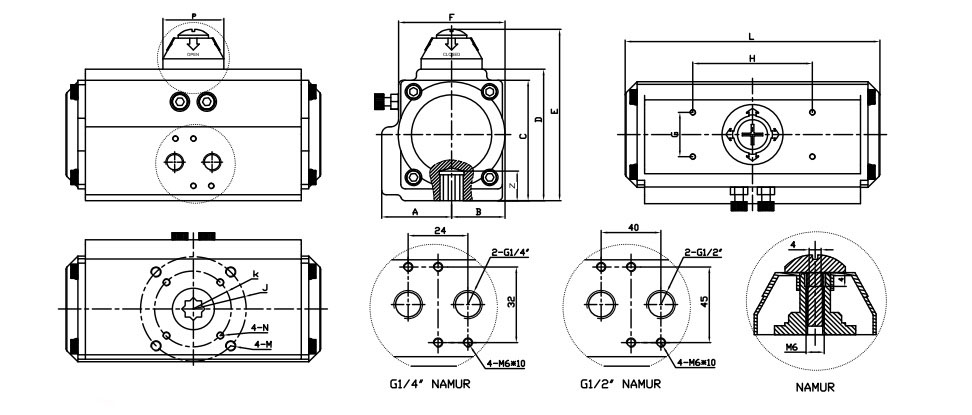

A high-pressure pneumatic ball valves integrates a high-pressure ball valve with a double or single-acting pneumatic piston actuator, using pneumatic power for operation. This type of valve is employed in high-pressure pipeline systems found in gas stations, tank trucks, aviation, and medical facilities. The valve’s connections can be internal or external threads (g / NPT), welded, or ferrule type. It is typically constructed from stainless steel, alloy, or carbon steel, with stainless steel being the most commonly used material for these high-pressure pneumatic ball valves.

model: DK66-HG

Julat Saiz: 1/4″ to 2″

Julat Tekanan: 10~40MPa / 1450~5800 PSI

Bahan: Keluli Tahan Karat 304/316

DELCO High Pressure Pneumatic Actuated Ball Valve

Parameter Teknikal Penggerak Injap

| Lakonan berganda | Udara untuk membuka, udara untuk menutup, kegagalan pembekal udara untuk mengekalkan kedudukan semasa |

| T/C lakonan tunggal | Udara untuk membuka, mengganggu udara untuk menutup, kegagalan udara untuk menutup |

| Lakonan tunggal TIADA | Udara untuk menutup, mengganggu udara untuk membuka, kegagalan udara untuk membuka |

| Aksesori pilihan | Injap solenoid terbalik, kotak suis had, injap penurun penapis udara, penentu kedudukan, manual pemegang, injap pengunci. |

Parameter Teknikal Badan Injap

| Badan | Komponen injap | ||

| Julat saiz | DN15~DN50 | Bahan pengedap | PTFE, PPL |

| Bahan badan | Keluli tahan karat | Bahan teras | Keluli tahan karat |

| End connection | Thread | Bahan batang | Keluli tahan karat |

| Tekanan operasi | 10.0MPa~40.0MPa(1450~5800psi) | Media yang berkenaan | Ultra high-pressure liquid, water, oil, gas |

| Struktur | Teras bola terapung | ||

Pemproses sumber udara: Menggabungkan fungsi penapisan, pengurangan tekanan dan pelinciran, memastikan tekanan alur keluar yang stabil. Tersedia dalam pemasangan dua keping untuk menapis udara instrumen termampat dan konfigurasi tiga keping untuk pelinciran tambahan.

Injap solenoid pneumatik: Mengawal pembukaan dan penutupan injap pneumatik dengan mengmagnetkan dan menyahmagnetkan untuk mengarahkan aliran gas berdasarkan isyarat voltan. Menawarkan kawalan tepat ke atas operasi injap, yang biasa digunakan untuk menguruskan sumber gas dan aliran litar.

Suis had: Mengesan status injap dan mengeluarkan isyarat untuk kedudukan terbuka atau tertutup. Kritikal dalam sistem kawalan automatik, mengesahkan dan melaksanakan program seterusnya, menyediakan perlindungan interlock injap, dan menunjukkan penggera jauh dalam sistem.

Kedudukan injap: Penting untuk kawalan tepat ke atas kedudukan injap dalam injap kawalan pneumatik, membandingkan anjakan batang injap dan isyarat keluaran pengawal, melaraskan isyarat keluaran penggerak dengan sewajarnya.

Peranti manual: Melengkapkan pemasangan penggerak pneumatik, memudahkan operasi manual atau pneumatik untuk injap rama-rama dan bola dengan bukaan 90°. Memastikan fleksibiliti dan fleksibiliti dalam operasi injap, membolehkan kawalan manual dan automatik mengikut keperluan.

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi