BLOG

Injap DELCO Menyediakan Pelbagai Penyelesaian Optimum Untuk Injap Perindustrian, Terutamanya Untuk Injap Kawalan.

TAG

Hubungi Kami

Electric Valves vs Traditional Valves: Key Considerations

- Pagi Jiang

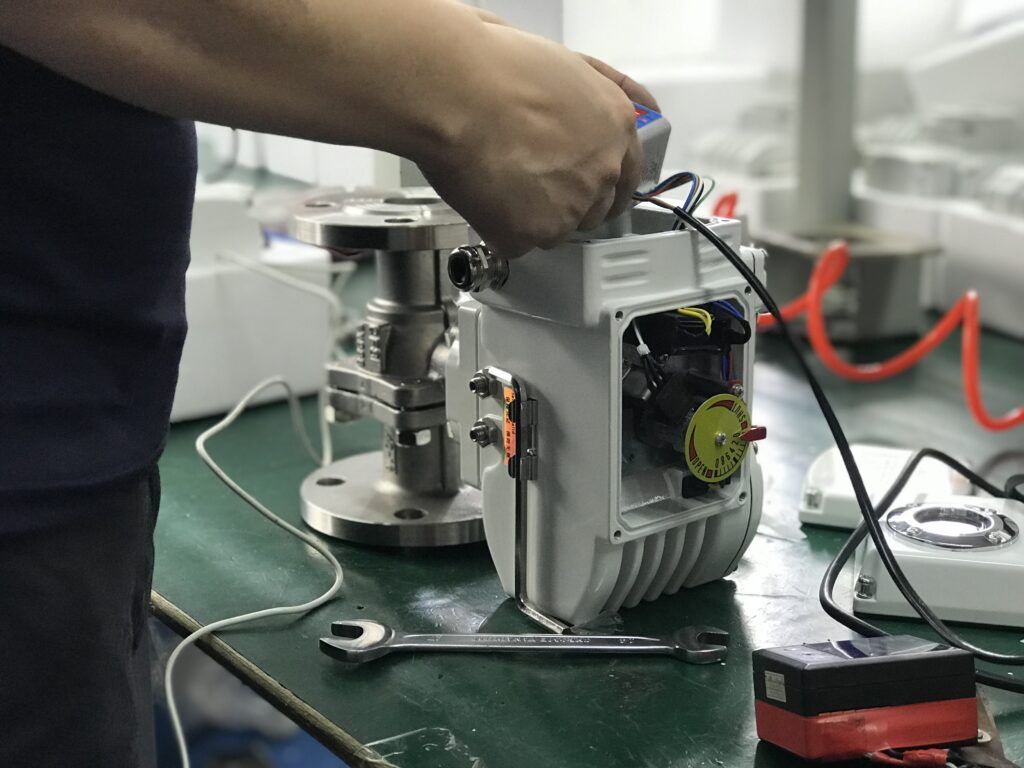

Injap elektrik and traditional valves serve crucial roles in industrial processes by regulating the flow and direction of various fluids, including water, oil, and chemicals. Each type of valve has its unique advantages and limitations, making them suitable for different applications. Here’s a detailed comparison to help you understand when to choose electric valves over traditional ones.

Injap Elektrik

Kelebihan:

- Ease of Installation: Injap elektrik are driven by motors, which simplifies installation. Unlike pneumatic valves, they do not require additional components like compressors, solenoid valves, or piping.

- Low Failure Rate: They generally have fewer components that wear out compared to pneumatic systems, leading to reduced maintenance and downtime.

- Automation Compatibility: They integrate seamlessly with existing control systems, making them ideal for automated processes.

Usage Notes:

- Switch Positioning: Ensure the actuator switch is in the correct position before operation. Set it to “REMOTE” for control via the SCADA system, or “LOCAL” for manual operation.

- Operation Monitoring: When operating manually, check the valve’s position indicator and ensure the valve opens or closes as required. For precise adjustments, use fine-tuning to achieve the desired position.

- Initial Adjustment: When adjusting the stroke and torque controllers, monitor the valve’s movement closely to prevent malfunction. If the valve doesn’t reach the specified position, immediately perform an emergency stop.

Traditional (Pneumatic) Valves

Kelebihan:

- Kos-Efektif: Pneumatic valves are generally less expensive and easier to maintain.

- High Speed: They offer faster operation compared to electric valves, which is advantageous for applications requiring quick response times.

- Precision Control: Pneumatic systems provide high precision in regulating flow.

Kelemahan:

- Environment Sensitivity: Pneumatic valves are susceptible to variations in air pressure and can be affected by environmental conditions such as humidity, which can freeze the air supply in colder climates.

- Additional Components Required: They need a stable air supply and additional components like compressors, which can complicate installation and increase operational costs.

Comparative Analysis

Power Source:

- Electric Valves: Operated by electric motors, suitable for large diameter pipes and are unaffected by environmental conditions.

- Pneumatic Valves: Powered by compressed air, effective for smaller pipes and gaseous media but can be influenced by air pressure fluctuations.

Speed and Precision:

- Electric Valves: Typically slower and less precise but offer better control over large-diameter applications.

- Pneumatic Valves: Faster and more precise, ideal for applications requiring rapid and accurate adjustments.

Safety and Environment:

- Electric Valves: Limited options for explosion-proof models and may not perform well in extremely humid environments.

- Injap Pneumatik: More cost-effective explosion-proof options and generally better suited for environments with fluctuating temperatures.

Cost Considerations:

- Injap Elektrik: Higher initial cost but potentially lower long-term maintenance costs if properly maintained.

- Pneumatic Valves: Lower upfront cost but may incur additional expenses due to the need for a reliable air supply and maintenance in varying environmental conditions.

Kesimpulan

Choosing between electric and pneumatic valves depends on your specific requirements, including the type of fluid, pipe size, speed, precision, and environmental conditions. Electric valves are preferable for automated systems with less environmental impact, while pneumatic valves are advantageous for applications needing quick operation and cost-effective solutions. Evaluate your needs carefully to select the most appropriate valve type for your application.