Kami bukan sahaja menyediakan sebut harga yang mudah, tetapi kami pakar dalam pemilihan, pengiraan dan lukisan.

Pilihan Teratas

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

DELCO Cast Iron Pneumatic Double Flange Butterfly Valves

Introducing the DELCO DK67-FB pneumatic butterfly valve, featuring a double-acting standard control mode with an optional single-acting configuration. This valve boasts a robust construction with a choice between cast iron or ductile iron bodies, and optional 304 or 316 stainless steel components. Designed to operate with an input air pressure range of 2.5 to 8 bar, it requires a minimum 2-inch flanged connection. The default seat material is NBR, with options for EPDM or PTFE seats to accommodate various applications including air, water, light oil, fuels, solvents, alcohol, and many acids.

DELCO offers a range of pneumatic actuator butterfly valves in wafer type, lugged type, and flanged configurations. Contact us for more information.

model: K67-FB

Julat Saiz: 2″ hingga 20″

Julat Tekanan: 1.0 hingga 6.4MPa

Bahan: Cast Iron, Cast Steel, Ductile Iron, Stainless Steel

DELCO Trieccentric Butterfly Valve with pneumatic actuator

Ciri-ciri Utama:

- Long-lasting performance

- Eco-friendly

- Easy to install

- Can be installed or removed without dislocating the pipe system

- Capable of throttling flow, suitable for large diameters

- Quarter-turn rotation mechanism

- Meets GB, ANSI, JIS, and DIN standards

- Flange end connection type

- Suitable for various mediums including water, oil, air, and gas

For further information, please refer to our detailed catalog.

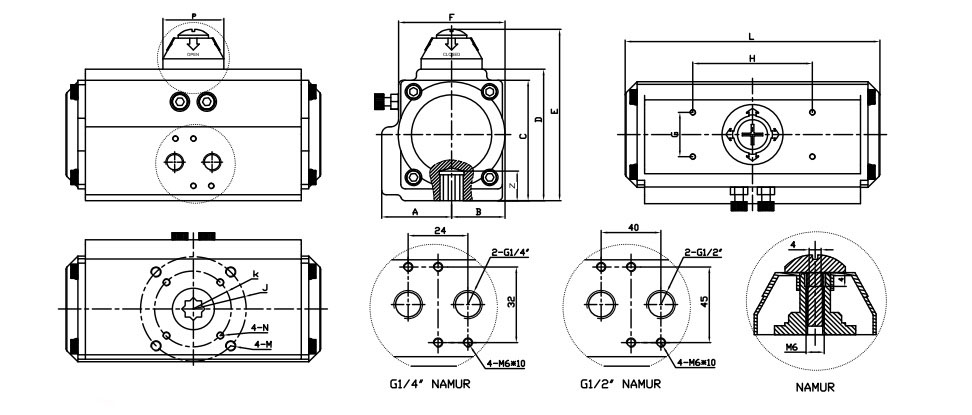

Parameter Teknikal Penggerak Injap

| Lakonan berganda | Udara untuk membuka, udara untuk menutup, kegagalan pembekal udara untuk mengekalkan kedudukan semasa |

| T/C lakonan tunggal | Udara untuk membuka, mengganggu udara untuk menutup, kegagalan udara untuk menutup |

| Lakonan tunggal TIADA | Udara untuk menutup, mengganggu udara untuk membuka, kegagalan udara untuk membuka |

| Aksesori pilihan | Injap solenoid terbalik, kotak suis had, injap penurun penapis udara, penentu kedudukan, manual pemegang, injap pengunci. |

Parameter Teknikal Badan Injap

| Bahan Cakera | 3.4, 316, 316L, 1.4529, 2507 | Acting Model | Double Acting/Spring Return |

| Air Supply Pressure | 2.5 to 8 Bar | Certification | ISO 9001, CE, TUV, SGS |

| Applicable Standard | GB, ANSI, JIS,DIN | Accessories | Positioner,Limit Switch,F.R.L |

| Port Size | 2″-20″ | Tamat Sambungan | Bebibir |

| Operating Pressure | 1.0-6.4 MPA | Media | Water, Oil, Air, Gas etc. |

| Body Material: | Cast Iron, SS, WCB | Working Temperature | -30°C to 180°C |

Pemproses sumber udara: Menggabungkan fungsi penapisan, pengurangan tekanan dan pelinciran, memastikan tekanan alur keluar yang stabil. Tersedia dalam pemasangan dua keping untuk menapis udara instrumen termampat dan konfigurasi tiga keping untuk pelinciran tambahan.

Injap solenoid pneumatik: Mengawal pembukaan dan penutupan injap pneumatik dengan mengmagnetkan dan menyahmagnetkan untuk mengarahkan aliran gas berdasarkan isyarat voltan. Menawarkan kawalan tepat ke atas operasi injap, yang biasa digunakan untuk menguruskan sumber gas dan aliran litar.

Suis had: Mengesan status injap dan mengeluarkan isyarat untuk kedudukan terbuka atau tertutup. Kritikal dalam sistem kawalan automatik, mengesahkan dan melaksanakan program seterusnya, menyediakan perlindungan interlock injap, dan menunjukkan penggera jauh dalam sistem.

Kedudukan injap: Penting untuk kawalan tepat ke atas kedudukan injap dalam injap kawalan pneumatik, membandingkan anjakan batang injap dan isyarat keluaran pengawal, melaraskan isyarat keluaran penggerak dengan sewajarnya.

Peranti manual: Melengkapkan pemasangan penggerak pneumatik, memudahkan operasi manual atau pneumatik untuk injap rama-rama dan bola dengan bukaan 90°. Memastikan fleksibiliti dan fleksibiliti dalam operasi injap, membolehkan kawalan manual dan automatik mengikut keperluan.

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi