Kami bukan sahaja menyediakan sebut harga yang mudah, tetapi kami pakar dalam pemilihan, pengiraan dan lukisan.

Pilihan Teratas

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

DELCO Cast Iron Multi Turn Wafer Electric Butterfly Valves

The Multi Turn Wafer Electric Butterfly Valves is primarily utilized for powder material hoppers and switch boxes, serving as an effective solution for managing powdery or granular materials within silos. It is suitable for all types of powdery and granular materials, employing gravity closure material valves and pneumatic transmission. These valves can be installed in dry material hoppers, bins, silos, or beneath various types of spiral conveyors, and they can also connect with pneumatic conveying pipelines. Due to their specialized structure and the use of engineering materials, Multi Turn Wafer Electric Butterfly Valves are always a very economical and efficient choice.

Model: Multi Turn Wafer Electric Butterfly Valve

Size Range: 2” to 40”

Pressure Range: 1.6-6.4Mpa

Material: Cast Iron or Stainless Steel 304/316

Multi Turn Wafer Motorized Butterfly Valve

Multi-turn electric valves find significant applications across industries such as electric power, metallurgy, petroleum, chemical engineering, paper-making, and sewage disposal. These actuators are crucial for controlling gate valves, ensuring efficient operation of various industrial processes.

Applications in Different Industries

- Electric Power: Regulating water and steam flows in power plants to maintain efficiency and safety.

- Metallurgy: Controlling the flow of metals and gases in metallurgical processes for optimal conditions.

- Petroleum: Precisely managing crude oil and natural gas flows in refineries and pipelines for safe and efficient processing.

- Chemical Engineering: Handling chemical flows to maintain process integrity and safety in chemical plants.

- Paper-Making: Regulating the flow of liquids and chemicals for consistent quality in paper production.

- Sewage Disposal: Managing wastewater flow for effective treatment and disposal in sewage treatment facilities.

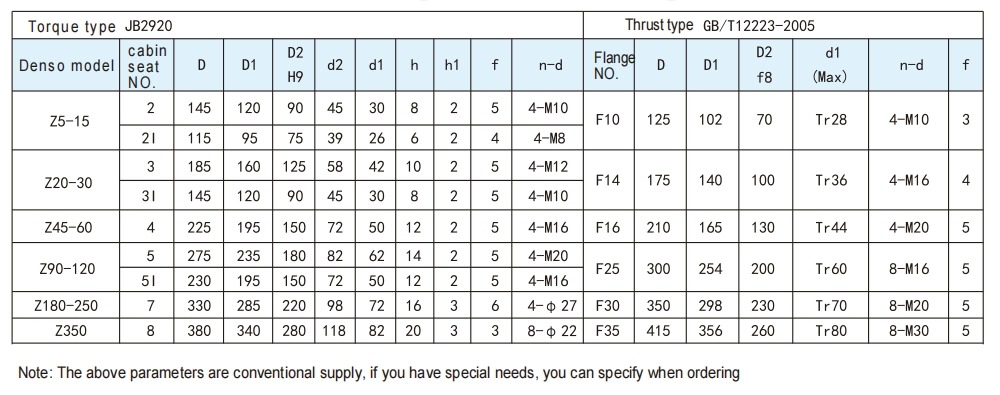

Technical Parameters of Multi-turn Actuator

| Bekalan kuasa | am: fasa tunggal 220v, tiga fasa 380v(50Hz), jarak jauh DC24V |

| istimewa: 110v fasa tunggal, 415v tiga fasa, 660v(50Hz, 60Hz) | |

| Persekitaran kerja | Suhu ambien: -20 ~ + 60 ℃ (persekitaran suhu khas boleh disesuaikan) |

| Kelembapan relatif: 95% (pada 25 ° C) | |

| Jenis luar boleh digunakan di tempat tanpa bahan mudah terbakar / letupan dan menghakis | |

| d saya | terpakai untuk kawasan kerja bukan penggalian untuk lombong arang batu |

| d saya BT4 | terpakai kepada alam sekitar dengan campuran gas bahan letupan IIA, gred IIB TL-T4, boleh digunakan di kilang |

| Tahap perlindungan | Jenis luar dan jenis kalis letupan ialah IP55 (IP65, IP67) |

| Masa bekerja | masa singkat 10 minit (15-60 minit untuk pesanan khas) |

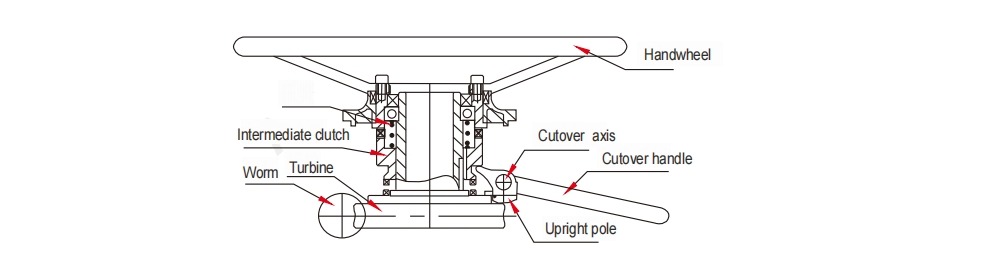

Multi-turn valve electric actuator Connection size

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi

Dapatkan Sebut Harga Pantas

SYOR

-

DELCO DK07 Pilot Operated Diaphragm Type Stainless Steel Solenoid Valve

Injap Solenoid yang dikendalikan oleh Juruterbang Baca lagi