BLOG

Injap DELCO Menyediakan Pelbagai Penyelesaian Optimum Untuk Injap Perindustrian, Terutamanya Untuk Injap Kawalan.

TAG

Hubungi Kami

Top Flow Control Valve Manufacturers: Choose the Best Supplier

- Injap DELCO

- Flow Control Valves: Key Functions and Importance of Manufacturer Selection

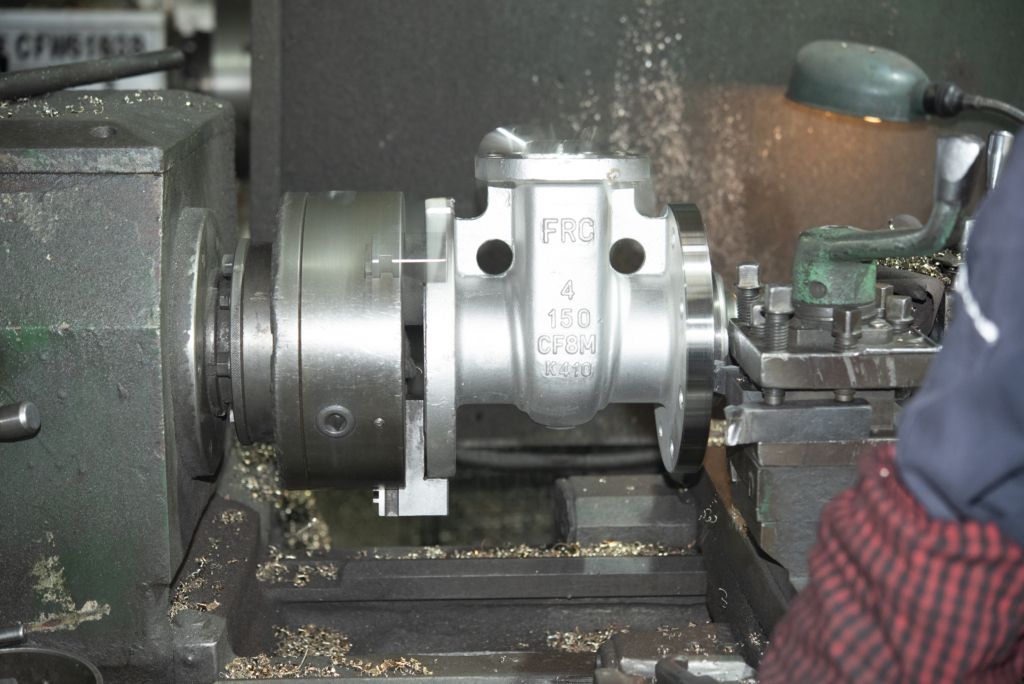

Flow control valves (FCVs) are critical components in industrial, aerospace, and fluid systems, designed to regulate the flow rate or pressure of liquids or gases. Their primary functions include:

Precise Flow Regulation: By adjusting the cross-sectional area of the flow path (e.g., via butterfly valves or orifice plates), FCVs ensure optimal system performance. For example, in aircraft air conditioning systems (A320), FCVs like PN 1806X manage bleed-air supply to maintain cabin pressure and temperature.

Multi-Mode Operation: Many FCVs support both main (electrical) and backup (pneumatic) modes. In backup mode, pressure regulators and solenoid valves (e.g., PN 1806X’s downstream limiter) ensure fail-safe operation during electrical failures.

Adaptability: Configurations range from simple on/off control to advanced pressure reduction or flow sustainment, with options for custom solutions.

Why Manufacturer Expertise Matters:

Technical Precision: High-quality FCVs integrate components like Hall-effect position sensors, differential pressure sensors (DPS), and duplex actuators for reliability. Reputable manufacturers use materials like 16Mn steel and corrosion-resistant coatings to enhance durability.

Certified Performance: Trusted suppliers adhere to standards like pressure compensation and feedback positioning technologies, ensuring valves operate seamlessly in extreme conditions (e.g., -15°C to 220°C).

Customization: Specialized needs (e.g., aviation or hydraulic systems) require tailored designs, such as flange-mounted valves or integrated ACSC (Air Conditioning System Controller) compatibility.

1.Flow Control Valves (FCVs) regulate fluid flow or pressure in systems like oil & gas, water treatment, and chemical processing. Key functions:

- Flow adjustment via valve openings (e.g., needle or butterfly valves).

- Pressure compensation to stabilize flow under varying conditions.

- Safety isolation during emergencies (e.g., engine fires).

- Top Applications:

- Oil & Gas: Balance multi-layer reservoir flows (e.g., Schlumberger’s TRFC-HD valves).

- Water Treatment: Maintain stable chemical dosing and pump protection.

- Chemical: Handle corrosive media with materials like 16Mn steel.

- Choose manufacturers with Hall-effect sensors, pressure-compensation tech, and certified materials (e.g., 16Mn steel).

2.How to Choose Flow Control Valve Manufacturers

Certifications: Prioritize API, ISO 9001, CE for quality assurance.

Valve Types: Ensure options like electric, pneumatic, or control valves fit your system.

Supply Chain: Verify production capacity and delivery speed (e.g., ocean/air logistics).

Support: Opt for 24/7 technical help and preventive maintenance plans.

Customization: Seek suppliers offering tailored solutions (e.g., flange/threaded designs).

Example: Manufacturers like Delco Flow (API-certified) or Hayward (thermoplastic valves) excel in these areas.

3.Top 5 Global Flow Control Valve Manufacturers & Comparisons (2025 Update) Industry-Leading Manufacturers

- Unique Service: Localized supply chain for urgent orders.

- Key Strengths: Custom solutions (flange/threaded designs).

- Key Strengths: Industrial hydraulic systems, mobile machinery solutions.

- Flagship Tech: Smart Fluid 4.0 (AI-powered flow optimization).

- Key Strengths: Diverse fluid control (hydraulic, pneumatic, and instrumentation valves).

- Flagship Products: Apitech high-precision valves, Colorflow real-time monitoring systems.

- Key Strengths: Heavy machinery hydraulics (piston pumps, proportional valves).

- Certifications: ASME 2500# high-pressure standards for extreme conditions.

- Key Strengths: Hydrogen energy and clean tech (e.g., Blakeborough hydrogen-compatible valves).

- Certifications: ISO 15848-1 (leakage) and ISO 19880-3 (hydrogen safety) certified.

4.Why Choose Delco Valves?

Final Tip: For cost-effective, fast, and tailored solutions, trust Delco Valves—combining German engineering with localized agility.

Need Flow control valves samples or audits? Request industry reports (e.g., 2024 Valve Rankings) or contact suppliers directly.