แท็ก

ติดต่อเรา

วาล์วความปลอดภัย: หลักการ ประเภท และการใช้งาน

- เช้าเจียง

Safety valves are essential safety devices in industrial equipment, primarily used to prevent damage and accidents caused by excessive pressure. This article explores the working principle, types, and widespread applications of safety valves to enhance your understanding of their function and importance.

Working Principle of Safety Valves

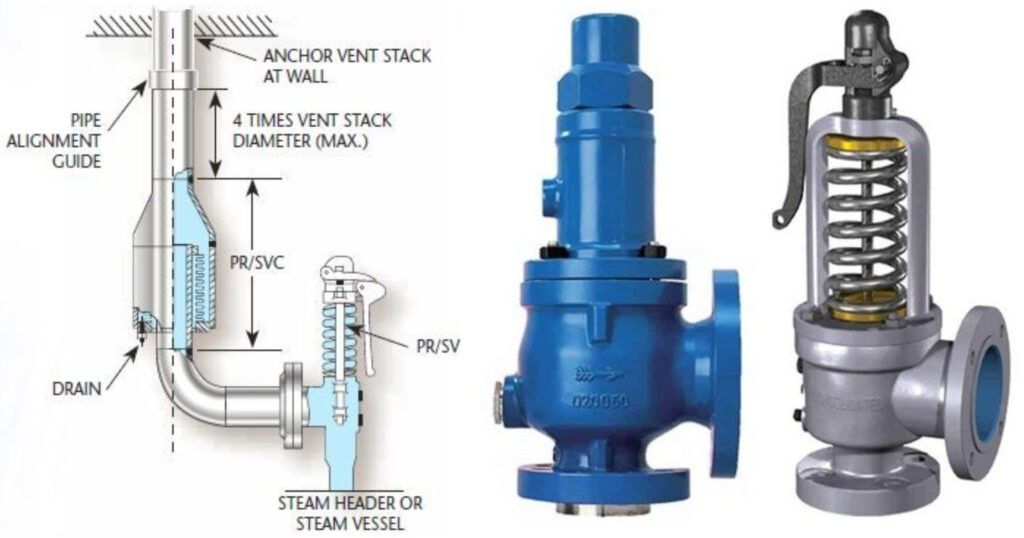

The basic working principle of a วาล์วเซฟตี้ is that when the internal pressure of a device or pipeline exceeds a set limit, the safety valve automatically opens to release excess pressure, thereby protecting the equipment from damage. When the pressure returns to a safe level, the safety valve automatically closes, maintaining normal system operation.

Working Process:

- Pressure Monitoring: The built-in spring or pneumatic mechanism constantly monitors the internal pressure.

- Valve Opening: When the internal pressure exceeds the set value, the valve automatically opens to release excess gas or liquid.

- Pressure Recovery: When the pressure decreases to a safe range, the valve automatically closes, ensuring system stability.

Types of Safety Valves

Safety valves can be categorized into several main types based on their structure and working principle:

1. Spring-Loaded Safety Valves

Spring-loaded safety valves are the most common type. They use spring force to keep the valve closed. When system pressure exceeds the set value, the spring compresses, and the valve opens. This type is simple in design and responds quickly, making it widely used in various industrial applications.

2. Pneumatic Safety Valves

Pneumatic safety valves operate based on the pressure of gas or liquid to control the opening and closing of the valve. They are suitable for high-pressure or high-temperature environments and can handle large flow rates, making them ideal for complex industrial systems.

3. Electric Safety Valves

Electric safety valves are driven by electric power, allowing for remote control and monitoring. They excel in applications requiring high automation and precise control.

Industrial Applications of Safety Valves

Safety valves play a critical role in multiple industries. Here are some key application areas:

1. Oil and Gas Industry

In the storage and transportation of oil and gas, safety valves prevent leaks or explosions caused by excessive pressure, ensuring operational safety.

2. Chemical Industry

Chemical equipment often operates under high pressure. Safety valves effectively prevent accidents caused by overpressure in reaction vessels, protecting both equipment and personnel.

3. Power Industry

In power plants, safety valves are used in boilers and steam systems to prevent overpressure conditions, ensuring system stability and safety.

4. Pharmaceutical Industry

4. Pharmaceutical Industry

Considerations for Choosing Safety Valves

When selecting an appropriate วาล์วเซฟตี้, consider the following factors:

- Set Pressure: Ensure that the safety valve’s set pressure aligns with the operational requirements of the equipment.

- Type of Medium: Choose the right safety valve based on the characteristics of the medium (gas or liquid).

- Environmental Conditions: Select safety valves suitable for the temperature, humidity, and other environmental conditions.

บทสรุป

Safety valves play an indispensable role in industrial production, effectively preventing equipment damage and accidents due to excessive pressure. When selecting and using safety valves, it is essential to consider operational conditions, medium characteristics, and industry requirements to ensure the safety and stability of equipment. By gaining a deeper understanding of the working principles and types of safety valves, you can better protect industrial equipment and personnel.