BLOG

DELCO Valve Provide Various Optimal Solution For Industrial Valves, Especially For Control Valves.

BLOG

- The Versatility of Motorized Valves

- Electric Valves vs Solenoid Valves

TAGS

Contact Us

Valve Dynamics Unveiled: Electric Valves vs Solenoid Valves

- Morning Jiang

Exploring the Distinctions: Electric Valves vs Solenoid Valves

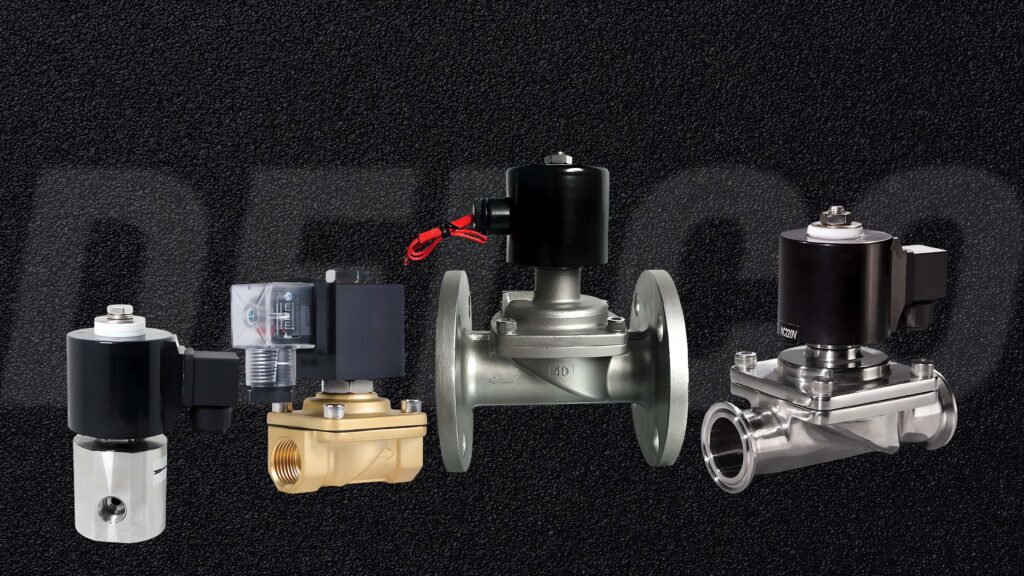

In the realm of fluid control systems, the distinction between electric valves and solenoid valves might seem subtle to the uninitiated eye. However, understanding their structural variances, functional disparities, and diverse applications is crucial for optimizing their utilization in various industrial settings. Let’s delve into the nuances that set these two valve types apart, shedding light on their unique characteristics and optimal applications.

Structural Variances:

At the core of distinguishing electric valves from solenoid valves lies their structural composition. A solenoid valve typically comprises a coil, valve body, pilot head, and rubber pad. In contrast, an electric valve consists of an electric actuator and valve body. This fundamental difference in structure often translates to differences in size, with solenoid valves generally being more compact compared to electric valves. This compactness makes solenoid valves a preferred choice for applications constrained by limited space.

Functional Disparities:

While both solenoid valves and electric valves serve the purpose of regulating fluid flow, their functionalities exhibit notable disparities. Solenoid valves are characterized by their rapid opening and closing speeds, making them suitable for applications requiring frequent switching between open and closed positions or dealing with low flow rates and pressures. On the other hand, electric valves offer a broader range of control, allowing for precise adjustment of the valve’s opening degree. This capability enables electric valves to operate in multiple states, including fully open, fully closed, and partially open/closed positions, thereby providing enhanced control over the flow rate of the medium in the pipeline—a functionality not achievable with solenoid valves.

Applications in Practice:

Understanding the unique strengths and limitations of electric valves and solenoid valves is essential for selecting the most appropriate valve type for specific applications. Solenoid valves excel in on-off control of liquid and gas pipelines, typically employed in scenarios requiring two-position control, especially in smaller pipe systems. Conversely, electric valves find their niche in systems necessitating regulation or intelligent control of fluid flow. They offer the versatility to modulate the medium flow of liquid, gas, or air systems with analog quantity regulation, making them ideal for applications where precise control and adjustment are paramount. Moreover, electric valves can also function as two-position switch controls in larger valve and air system setups, further expanding their applicability.

Conclusion:

In conclusion, while electric valves and solenoid valves may share similar functionalities at a superficial level, a closer examination reveals significant disparities in their structural composition, functional capabilities, and optimal applications. By understanding these distinctions, industrial practitioners can make informed decisions regarding the selection and deployment of valves in fluid control systems, ensuring optimal performance, efficiency, and reliability in various industrial processes.

As a specialized company in valve design and production, we are committed to providing high-quality valve solutions tailored to your specific needs. Please feel free to reach out to us for any inquiries or assistance regarding valve selection and customization.