標籤

聯絡我們

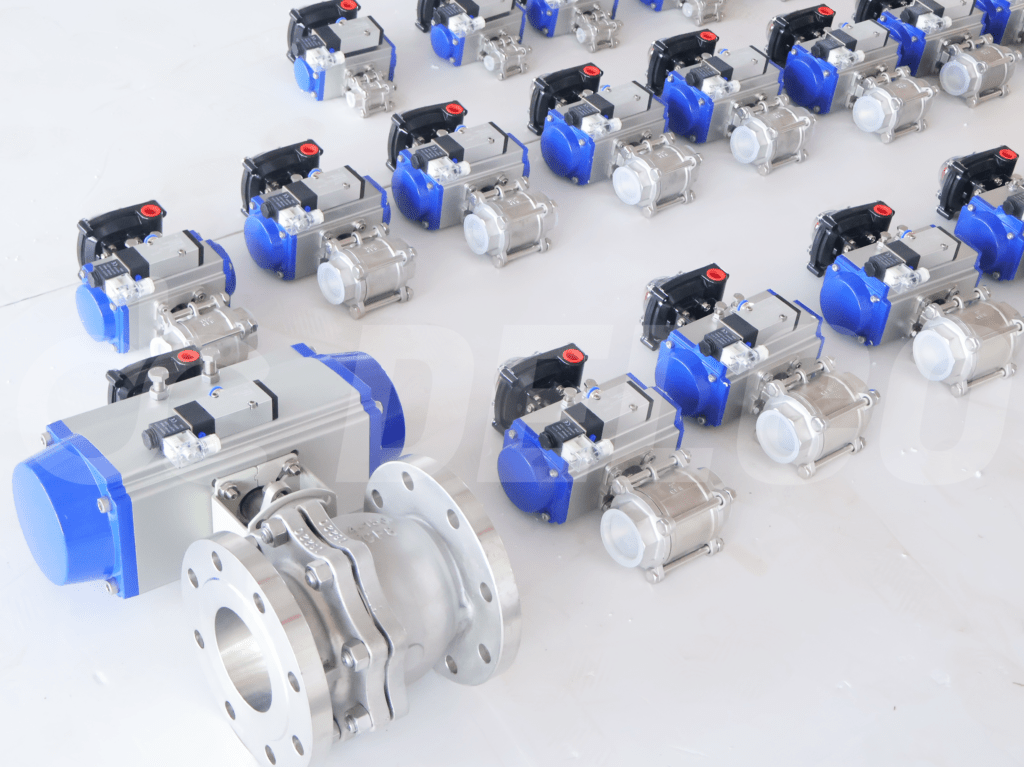

Pneumatic Actuator Valve: A Comprehensive Guide

- DELCO 閥門

這 Pneumatic Actuator Valve is an important fluid control device in flow control systems. In this article, DELCO Valve analyzes in detail its characteristics, areas of application and selection recommendations to help you better understand this device.

Working Principle of Pneumatic Actuator Valve

Pneumatic Actuator Valve drives the piston or diaphragm of the pneumatic actuator through compressed air to drive the valve stem action to realize the opening or closing of the valve. Pneumatic actuator is divided into single-acting (spring reset) and double-acting (completely driven by the air source) two kinds, applicable to different working conditions.

Advantages of Pneumatic Actuator Valve

- Fast response: suitable for working conditions that require frequent opening and closing.

- High efficiency and energy saving: compressed air as the power source, low operating costs.

- Strong adaptability: can be used with many types of valves to meet the needs of different working conditions.

Application Areas

- Oil & Gas Industry: Control of fluid flow and pressure in transportation pipelines.

- Chemical and pharmaceutical industry: handling corrosive media, automated production.

- Water treatment and supply systems: precise regulation of water flow, optimizing the use of resources.

- Food and beverage industry: ensure fluid control under hygienic conditions.

How to choose the right Pneumatic Actuator Valve

- Actuator type: single-acting suitable for emergency shutdown conditions, double-acting suitable for frequent operation.

- Valve body material: such as stainless steel for corrosive media, cast iron for ordinary conditions.

- Matching of air source pressure and torque: ensure that the actuator can drive the valve to work properly.

Installation and maintenance recommendations

- Installation precautions: ensure that the valve and pipeline centering, to avoid leakage caused by improper installation.

- Routine maintenance: Regularly check the air supply and seal condition to prevent leakage or jamming.

- Troubleshooting: If the action is slow or ineffective, it is necessary to check the gas supply pressure and actuator connection.

Contact DELCO For Quick Quote

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email [email protected].